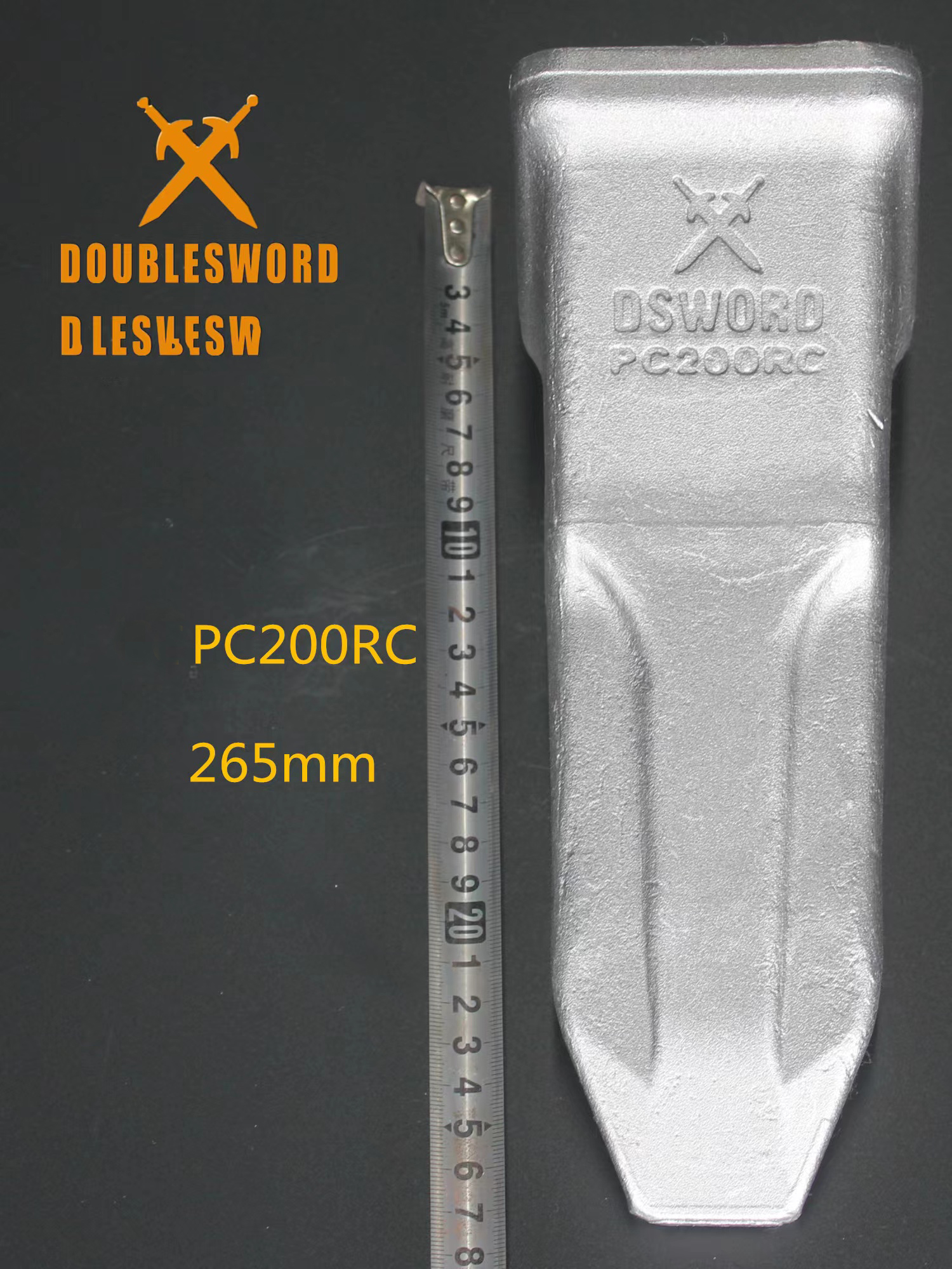

Wear resistant and durable, such special bucket teeth make mine operation efficient and worry free,Bucket Teeth

CQC The pure supplementary mining bucket tooth can not only improve the strength, but also increase the length, with both wear resistance and durability. It can meet the strict working conditions of the mine and help you conquer the mine easily!

01

Small bucket tooth

A variety of advanced industrial manufacturing technologies

Bucket teeth are important parts of excavators, similar to human teeth, which need to be strong and wear-resistant and can withstand long-term tests.

The bucket tooth is connected with the bucket tooth seat by the lock pin. Since the worn part of the bucket tooth is the tooth tip, when it needs to be replaced, only the bucket tooth can be replaced.

Excavator Bucket Teeth

According to the use characteristics of bucket teeth

Use characteristics

The bucket teeth must have high wear resistance, so as to effectively extend the service time of the bucket teeth. At the same time, the bucket teeth also need strong toughness, which can withstand the impact of high strength and is not easy to break. In addition, because the amount of bucket teeth is very large, we must also have a good economy, so as to reduce our use costs. It can be said that our various advanced industrial manufacturing technologies are embodied in the small bucket teeth.

At present, bucket teeth of excavators can be divided into the following categories

classification

01

Rock tooth

Used for iron ore, stone ore, etc

02

Earthwork tooth

Used for earthwork, sand and gravel, etc

03

Conical tooth (also called tiger claw tooth)

Used in coal mine

02

How to replace a set of wear-resistant and durable bucket teeth

Through the above introduction, it is not difficult to find that the bucket teeth play a vital role in the working process of the excavator. So in the daily maintenance of the excavator, we might as well spend 2 minutes a day to check the bucket teeth.

When the bucket tooth tip is seriously worn, the force required for the bucket to cut in is bound to increase significantly during the excavation operation of the excavator, resulting in higher fuel consumption and affecting the working efficiency. Therefore, it is necessary to replace the bucket teeth with new ones when they are found to be seriously worn.

Now let’s take a look

How to correctly replace bucket teeth for excavators

*Tips: Please watch this video in WIFI!

03

Characteristics of Special Mine Teeth for KOSCO

● Strict selection of raw materials, less harmful impurities

Exquisite casting process with guaranteed quality

● Optimized structural proportion, strong penetration and more durable

● Material improvement, wear-resistant and hard to break

After investigating the needs of customers, KOSCO has deeply cooperated with well-known manufacturers to develop pure supplementary mining bucket teeth (casting shapes) that are more suitable for market conditions. It not only increases the strength of the bucket teeth, but also lengthens the length of the bucket teeth, giving consideration to wear resistance and durability, so as to meet the strict mining operation.

Stronger

More durable

Post time: Dec-12-2022