It is well known that the appearance, practicability and service life of a product are a direct manifestation of a product's craftsmanship, and are the three major elements for judging the pros and cons of a product. In the last issue, we introduced to you the improvement of the production process of the Heli Heavy Industries workshop and the positioning of the future development direction with the title of "New Development, New Trend". In this issue, we will introduce Heli Heavy Industries' products from more primitive materials and processes.

The content of chemical elements has always been a measure of the quality of steel materials. For example, an increase in the carbon content of steel will increase the yield point and tensile strength of the steel, while reducing its plasticity and impact properties.

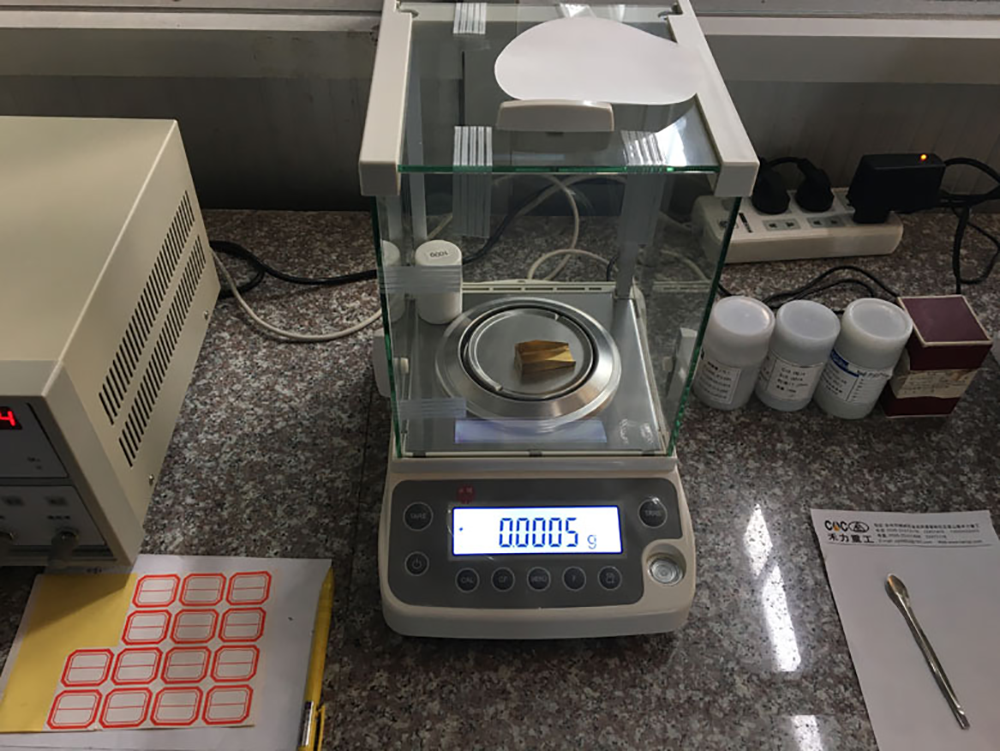

On the one-stop production line of Heli Heavy Industry, two test departments are set up. The first test department is located in the foundry, and is responsible for the inspection of product ingredients and the material inspection of the blanks. The second test department is set up in Heli. The production workshop of Li Heavy Industry is mainly responsible for regular sampling inspection of finished products and assisted inspection of heat treatment process. The laboratory is equipped with a carbon and sulfur analyzer, an intelligent multi-element analyzer, a metallurgical microscope, and so on.

6801-BZ/C Arc Combustion Carbon and Sulfur Analyzer

The 6801-BZ/C arc combustion carbon and sulfur analyzer will accurately analyze the carbon and sulfur content in the material. In addition to the impact of carbon on the hardness and plasticity of the steel, it also affects the atmospheric corrosion resistance of the steel. In an outdoor environment, the higher the carbon content, the more likely it is to be corroded. Therefore, the determination of carbon content is a necessary step in steel production. Sulfur is also a harmful element under normal circumstances. It causes the steel to produce hot brittleness, reduces the ductility and toughness of the steel, and causes cracks during forging and rolling. Sulfur is also detrimental to welding performance, reducing corrosion resistance. However, adding 0.08-0.20% sulfur to steel can improve machinability and is usually called free-cutting steel.

6811A intelligent multi-element analyzer

The 6811A intelligent multi-element analyzer can accurately measure the content of various chemical elements such as manganese (Mu), silicon (Si), and chromium (Cr). Manganese is a good deoxidizer and desulfurizer in the process of steel making. Adding an appropriate amount of manganese can improve the wear resistance of steel. Silicon is a good reducing agent and deoxidizer. At the same time, silicon can significantly increase the elastic limit of steel. Chromium is an important alloy element of stainless steel and heat-resistant steel. It can increase the hardness and corrosion resistance of steel, but at the same time reduce plasticity. Therefore, some steel fractures that occur during the heat treatment process are likely to be excessive chromium content.

Metallurgical microscope

In the production of the four-wheel area, the material of the supporting wheel base, the supporting wheel side cover and the guide wheel support is ductile iron, which has high requirements for the spheroidization rate. The metallurgical microscope can directly observe the spheroidization rate of the product.

In addition, nickel (Ni), molybdenum (Mo), titanium (Ti), vanadium (V), tungsten (W), niobium (Nb), cobalt (Co), copper (Cu), aluminum (Al), The content of elements such as boron (B), nitrogen (N), and rare earth (Xt) will all have an impact on the performance of the steel and must be controlled within a certain range.

The two laboratories are like two customs checkpoints, constantly monitoring Heli's materials, preventing the outflow of all substandard products, and delivering qualified and high-quality products to customers.

Post time: Aug-27-2021