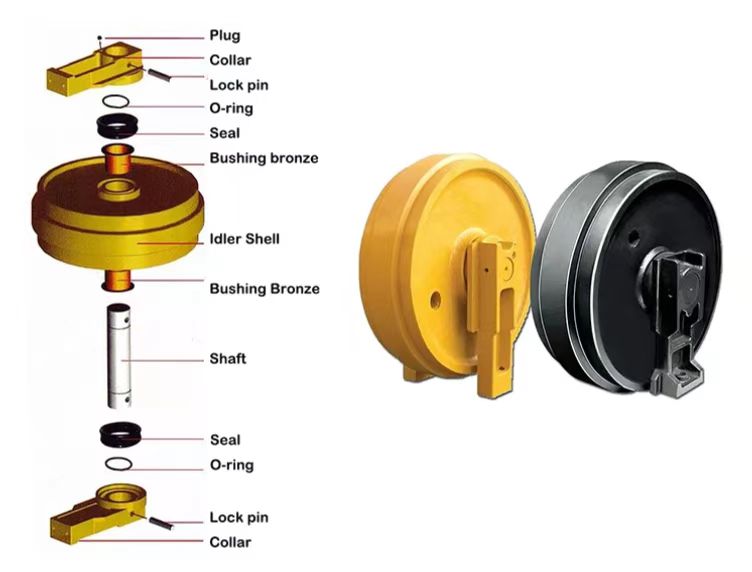

Excavator accessories – the key to prolong the service life of crawler!Turkey Excavator sprocket

Generally speaking, the crawler is one of the easily damaged parts in the excavator. What should be done to prolong its service time and reduce the replacement cost? Here are the key points to prolong the service life of the excavator track.

1. when there is soil and gravel in the excavator track, the included angle between the excavator boom and the stick arm shall be changed to keep it within 90 ° ~110 °; Then push the bottom of the bucket on the ground, hang the track on one side for several revolutions, so that the soil or gravel in the track can be completely separated from the track, and then operate the boom to make the track fall back to the ground. Similarly, operate the track on the other side.

2. when the excavator is moving, try to choose a flat road or soil surface, and do not move the machine frequently; When moving over a long distance, try to use a trailer to carry it, and try not to move the excavator around in a large range; It should not be too steep when climbing a steep slope. When climbing a steep slope, the route can be extended to slow down the slope and prevent the crawler from stretching and injury.

3. when the excavator turns, operate the boom of the excavator and the stick arm to maintain an included angle of 90 ° ~110 °, and push the bottom circle of the bucket on the ground, raise the tracks on both sides of the front end of the excavator so that they are 10cm~20cm above the ground, then operate the single track to travel, and operate the excavator to turn back, so that the excavator can turn (if the excavator turns left, operate the right track to travel, and then operate the swing control lever to turn right). If the goal cannot be reached once, the method can be used again until the goal is reached. This operation can reduce the friction between the track and the ground and the resistance of the road surface, so that the track is not easy to be damaged.

4. during excavator construction, the apron shall be flat. When excavating stones with different particle sizes, the apron shall be paved with gravel or stone powder and soil with smaller particles. The levelness of the apron can make the crawler of the excavator bear the force evenly and is not easy to be damaged.

5. during machine maintenance, check the tension of the track, maintain the normal tension of the track, and fill the track tension cylinder with grease in time. During inspection, move the machine forward for a certain distance (about 4 meters) before stopping.

Post time: Jun-21-2022