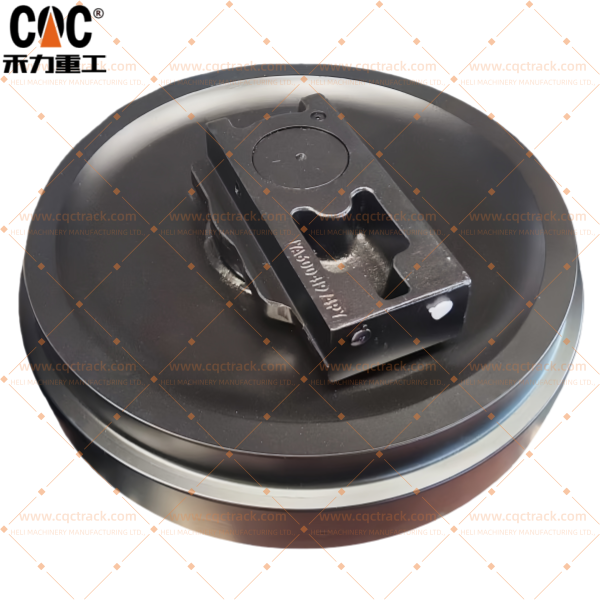

HITACHI YA60041974 ZX450 ZX470 ZX490 Track Idler Assy / Track Guide Wheel Assembly–Heavy duty excavator Track chassis component OEM&ODM manufacturer-HELI(cqctrack)

Comprehensive Technical Specification: HITACHI ZX450/ZX470/ZX490 Excavator Track Idler Assembly / Guide Wheel Assembly (P/N: YA60041974) – OEM & ODM Manufacturer: HELI (CQCTRACK)

1. Component Identification & System Integration

The Track Idler Assembly, interchangeably termed Track Guide Wheel Assembly (Original Part Number: YA60041974), is a front-end, precision-engineered chassis component integral to the undercarriage system of HITACHI ZX450, ZX470, and ZX490 model heavy-duty excavators. Manufactured by HELI (CQCTRACK) as both an Original Equipment Manufacturer (OEM) supplier and an Original Design Manufacturer (ODM) partner, this assembly is the definitive forward guide and primary tensioning terminus for the excavator’s track chain. Its design and performance are critical for ensuring longitudinal stability, proper track shoe ground engagement, and efficient power transmission during propulsion and counter-rotation maneuvers.

2. Primary Operational Functions & Kinematic Role

- Track Chain Guidance & Alignment: Provides a hardened, rotating datum surface that precisely guides the track chain’s link assemblies, ensuring continuous axial alignment as the chain enters the upper carriage path, thereby preventing lateral walk-off and derailment.

- Dynamic Tension Regulation: As the anchored point for the hydraulic or grease-filled track tensioning cylinder, the idler transmits adjustable forward force to the entire track chain. Maintaining optimal tension is paramount for minimizing power loss, reducing track “snap” or whip, and preventing premature wear on pins, bushings, and sprocket teeth.

- Impact Load Dissipation: Absorbs and distributes initial vertical and horizontal shock loads when the track chain makes contact during machine travel over irregular surfaces, protecting the track frame and structural welds from stress fatigue.

- Undercarriage Gauge Stabilization: Serves as the forward structural anchor that defines and maintains the correct track gauge (distance between the centerlines of parallel tracks), crucial for machine stability and straight-line tracking.

3. Detailed Structural Composition & Material Engineering

HELI’s ODM/OEM manufacturing process for the YA60041974 assembly involves advanced metallurgy and precision machining:

- Idler Wheel/Rim: Fabricated from forged and normalized alloy steel (e.g., 50Mn or equivalent). The running surface undergoes progressive induction hardening to achieve a deep, controlled hardness profile (typically surface hardness of HRC 58-62, with a tough core hardness of HRC 30-40), ensuring extreme abrasion resistance against track bushing contact while retaining impact strength.

- Integral Flanged Hub & Shaft: Features a high-strength, heat-treated alloy steel shaft that is either splined or keyed and pressed into a forged flange hub. The shaft bearing journals are precision-ground to micron-level tolerances and often hard chrome plated or nitrided for superior wear and corrosion resistance at the bearing contact surfaces.

- High-Capacity Bearing Configuration: Utilizes a matched pair of large-bore Tapered Roller Bearings (TRBs) or Double-Row Spherical Roller Bearings. This configuration is selected specifically to manage the immense radial loads from machine weight and the substantial axial thrust loads generated during aggressive turning and side-hill operation characteristic of the ZX450-490 class excavators.

- Advanced Multi-Component Sealing System: Incorporates a radial face seal combined with a floating side seal and an external multi-labyrinth dust guard. This triple-defense system is packed with high-viscosity, extreme pressure (EP) lithium-complex grease to create an impervious barrier against fine particulate abrasives (quarry dust, silica) and fluid intrusion, even under high-pressure washdown conditions.

- Adjustment Interface Components: Includes hardened and ground wear rings or replaceable slide bushings made of oil-impregnated sintered bronze or surface-hardened steel. These interface with the track frame’s adjustment slide, allowing smooth tensioning movement while being designed as sacrificial components to protect the core idler and frame structure.

- Lubrication Infrastructure: Fitted with high-pressure hydraulic-style grease fittings (e.g., ST-type) to facilitate routine maintenance of both the main bearing cavity and the sliding bushing surfaces.

4. HELI (CQCTRACK) OEM/ODM Manufacturing Capability

For the YA60041974 assembly, HELI operates under stringent OEM and ODM protocols:

- OEM Compliance: Manufactures components to exact Hitachi Engineering Standards (HES), including full material certification, dimensional conformity, and performance validation, often for direct supply to Hitachi’s assembly lines or authorized parts networks.

- ODM Expertise: Provides complete design-for-manufacturing (DFM) and value-engineering services, offering customized solutions such as material upgrades, seal enhancements, or weight optimization for specific operational environments without compromising performance specifications.

- Integrated Production Flow: Employs a closed-loop manufacturing process: CNC forging die design → automated forging → controlled cooling → rough machining → stress relieving → finish machining → computerized heat treatment → grinding & honing → ultrasonic cleaning → automated bearing/seal installation → laser marking → final testing.

- Quality Assurance & Traceability: Implements a full Material Test Report (MTR) system. Each batch undergoes non-destructive testing (MPI/DPI), hardness depth verification, seal pressure testing, and rotational torque analysis. Components are marked with unique lot codes for complete traceability.

5. Technical Specifications & Performance Data

- Dimensional Integrity: Conforms precisely to Hitachi’s specified Outside Diameter (O.D.), Total Width, Bore Diameter, Flange Height, and Bolt Pattern.

- Dynamic Load Rating: Engineered to exceed the dynamic load requirements for the ZX450-490 series, accounting for a minimum safety factor as per ISO 10262 or similar standards for earth-moving machinery.

- Seal Performance: Tested to withstand immersion and pressure washing per ISO 3457 (static sealing) with minimal grease egress or contaminant ingress.

- Environmental Tolerance: Designed for operational temperature ranges from -25°C to +80°C, with grease and seal compounds specified accordingly.

6. Application, Maintenance & Interchangeability

- Direct Application: Hitachi models ZX450LC, ZX470LCH, ZX490LCH, and their variant series.

- Interchangeability: A direct, bolt-for-bolt replacement for the original Hitachi YA60041974 assembly. Cross-referencing should always verify machine serial number ranges for potential engineering revisions.

- Wear Measurement & Service Life: Critical wear dimensions include rim O.D. reduction and flange width thinning. Regular measurement against factory specifications is essential. Service life is maximized by maintaining correct track tension and cleaning debris from the cavity between the idler and track frame.

- System-Based Replacement: For optimal undercarriage economy and performance, idler replacement should be evaluated alongside the condition of the track chain (pins & bushings), sprocket (rims or entire assembly), and carrier rollers to avoid accelerated wear on new components.

Conclusion

The HITACHI YA60041974 Track Idler/Guide Wheel Assembly for ZX450/ZX470/ZX490 excavators, produced by HELI (CQCTRACK), epitomizes the convergence of OEM precision and ODM manufacturing flexibility. Its design, rooted in superior material science, advanced heat treatment, and a multi-tiered sealing strategy, delivers the durability and reliability required for the most demanding excavation and mining applications. As a certified manufacturer, HELI ensures this critical undercarriage component not only meets but can exceed the rigorous performance standards set by Hitachi, providing end-users with a component that guarantees machine stability, operational efficiency, and extended service life for the entire track system.