XCMG Part#414101964 XE700 Tension Wheel/Front Idler Assembly-Manufactured by CQCTRACK

XCMG Part # 414101964: XE700 Tension Wheel/Front Idler Assembly – Manufactured by CQCTRACK

1. Product Overview & Functional Definition

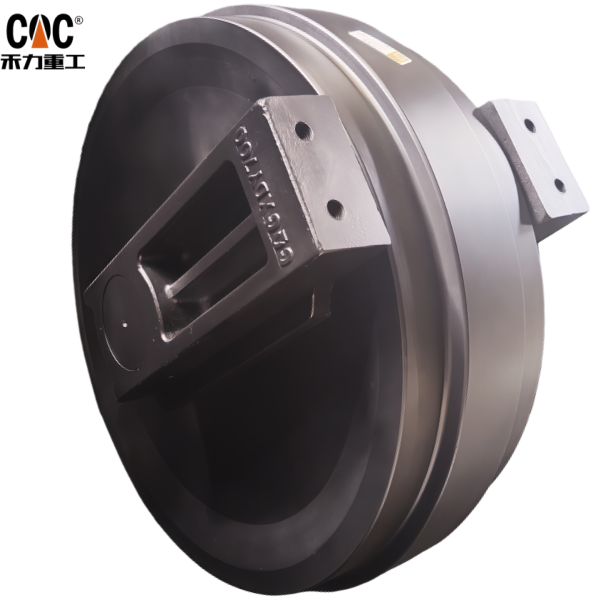

The XCMG 414101964 Tension Wheel/Front Idler Assembly, engineered and manufactured by CQCTRACK, is a precision aftermarket undercarriage component designed for the XCMG XE700 large hydraulic excavator. This assembly integrates two critical functions into a single, robust unit: it acts as the Tension Wheel for the track system’s adjustment and serves as the Front Idler guiding the track’s path. CQCTRACK, a specialist in undercarriage solutions, manufactures this assembly to deliver OEM-equivalent fit, form, and function, providing exceptional durability and reliability in severe operating conditions such as mining, heavy excavation, and rock quarries.

2. Comprehensive Technical Specifications & Engineering Data

| Parameter | Specification |

|---|---|

| OEM Part Number | 414101964 (100% Interchangeable) |

| Applicable Machine | XCMG XE700 Hydraulic Excavator |

| Component Designation | Tension Wheel / Front Idler Complete Assembly |

| Manufacturer | CQCTRACK (Certified Undercarriage Specialist) |

| Primary Material | Forged Alloy Steel (e.g., 42CrMo or equivalent) |

| Heat Treatment Process | Induction Hardening on the running surface (55-60 HRC); Through-Hardening and Tempering for the core (HB 320-380). |

| Bearing Assembly | High-Capacity, Metric Tapered Roller Bearings (e.g., ISO 355 Series). |

| Sealing System | Integrated Multi-Stage Sealing: Combination of Labyrinth Guards, Floating Face Seals, and Nitrile (NBR) Lip Seals. |

| Lubrication Point | Standard SAE Grease Nipple (Zerk Fitting). |

| Flange Design | Double-Flanged, Reinforced Web Structure for maximum impact resistance. |

| Corrosion Protection | Phosphate Conversion Coating or Electrostatic Epoxy Primer. |

3. In-Depth Mechanical Function & Operational Analysis

3.1. Tension Wheel Function: Dynamic Track Tensioning

The term “Tension Wheel” explicitly defines this component’s primary role in the track tensioning system. The assembly is housed within a tensioning carriage that slides within the track frame. Hydraulic pressure or mechanical force applied via a grease gun to the track tensioner cylinder pushes this entire assembly forward. This action increases the distance between the front idler and the sprocket, thereby applying precise static and dynamic tension to the entire track chain. Correct tension is critical for:

- Preventing Track Derailment: A properly tensioned track resists lateral disengagement.

- Optimizing Power Transmission: Reduces energy loss from track whip and slippage on the sprocket.

- Maximizing Component Life: Ensures even load distribution across the track rollers, carrier rollers, and sprocket, preventing premature wear.

3.2. Front Idler Function: Track Guidance and Load Support

As the Front Idler, this component is the non-driven pulley over which the track chain rotates. Its key mechanical functions are:

- Track Guidance: The robust, double-flanged design continuously interfaces with the inner guide ribs of the track links, maintaining strict lateral alignment and preventing the track from “walking” off the roller frame.

- Load Bearing: It supports the weight of the machine at the front of the undercarriage and absorbs the initial impact loads when the track encounters obstacles.

- Smooth Articulation: The precisely machined contour and hardened surface allow the track bushings to roll over with minimal friction and resistance, facilitating smooth travel motion.

3.3. Load Distribution and Structural Integrity

The assembly is subjected to extreme cyclical loads, including radial forces from machine weight and axial (thrust) forces from turning and side-sloping. The forged alloy steel construction and the high-precision tapered roller bearings are engineered to withstand these combined stresses, ensuring dimensional stability and preventing catastrophic failure.

4. Engineering Excellence & Material Advantages of CQCTRACK

- Forged Steel Construction for Superior Strength: Unlike cast components, CQCTRACK utilizes a forged alloy steel blank. The forging process aligns the grain flow of the metal to the contour of the part, resulting in a denser, more homogeneous microstructure with higher impact strength and fatigue resistance.

- Optimized Heat Treatment Profile: The induction hardened running surface provides maximum resistance to abrasion from the track chain, while the tough, through-hardened core ensures the component can withstand severe shock loads without cracking or deforming.

- Advanced Bearing and Seal Package: The assembly incorporates a floating face seal system as the primary seal. This design maintains a dynamic seal between two highly hardened metal faces, which is exceptionally effective at excluding fine, abrasive particles (like rock dust) and retaining grease, even under high-pressure washdowns. The tapered roller bearings are pre-set and pre-lubricated for optimal service life.

- Precision Machining and Dimensional Compliance: All critical interfaces—including the shaft journals, bushing bores, and external flanges—are machined on CNC equipment to maintain strict OEM tolerances. This guarantees a perfect fit with the XCMG XE700 track tensioning bracket and ensures proper track link engagement.

- Rigorous Quality Assurance: CQCTRACK implements a full quality control protocol, including material certification, hardness testing, and dimensional inspection, ensuring every assembly meets the performance requirements for heavy-duty excavation.

5. Application Context & Replacement Scenarios

This CQCTRACK assembly is the designated replacement for:

- Scheduled Undercarriage Rebuilds: Installed as part of a complete undercarriage replacement program to maintain peak machine performance and predictable wear rates.

- Component-Specific Failure: Replacing an OEM unit that has failed due to bearing seizure, flange wear-through, seal leakage, or rim cracking.

- Corrective Maintenance: Addressing issues of chronic track misalignment or an inability to maintain proper track tension due to a worn-out original idler.

6. Conclusion: A Superior Undercarriage Solution

The CQCTRACK XCMG 414101964 XE700 Tension Wheel/Front Idler Assembly represents a commitment to engineering excellence in the aftermarket undercarriage sector. By leveraging superior materials like forged steel, implementing an advanced floating face seal system, and adhering to precise manufacturing standards, CQCTRACK delivers a component that not only matches but in key areas of durability and seal performance, can exceed the original. For equipment managers seeking to maximize uptime and reduce the total cost of ownership for their XCMG XE700 fleet, this assembly provides a technically advanced and highly reliable solution.