VOLVO 14727597TL EC950 Forged Bucket Teeth – China Top quality forged bucket tooth manufacturer-HELI (DSWORD)

VOLVO EC950 Forged Bucket Teeth (14727597TL): Engineering Excellence by HELI (DSWORD) Forging

Executive Summary

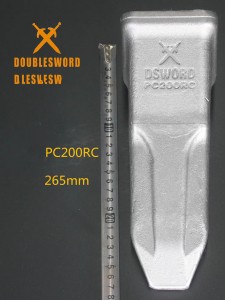

HELI (DSWORD), recognized as a premier forged bucket tooth manufacturer in China, presents its high-performance forged bucket tooth compatible with VOLVO EC950 excavators (Part Number: 14727597TL). Engineered for extreme abrasion and impact resistance, this product embodies our commitment to advanced metallurgy, precision forging technology, and rigorous quality control, delivering superior durability and total cost savings for heavy-duty mining and excavation operations.

1. Product Overview & Application

1.1 Primary Function

The bucket tooth is a critical wear component that serves as the primary interface between the excavator and the material being excavated. Its performance directly influences:

- Penetration Efficiency: Optimal geometry for reduced digging resistance.

- Load Retention: Effective shape for minimizing material spillage.

- Structural Protection: Shields the bucket lip and adapter from direct wear and impact forces.

1.2 Target Machine & Compatibility

- Primary Application: VOLVO EC950 Crawler Excavator.

- OEM Reference Part Number: 14727597TL.

- Note: Designed as a direct replacement, ensuring perfect fit with the VOLVO bucket adapter system without modification.

2. Advanced Manufacturing: The HELI (DSWORD) Forging Process

Our manufacturing philosophy centers on precision hot-forging, a superior method for producing high-stress wear components.

2.1 Precision Closed-Die Forging

- Material Selection: We use premium high-carbon, low-alloy boron steel billets, selected for their optimal balance of hardness, toughness, and wear resistance.

- Hot Forging: Steel is heated to a precise austenitizing temperature and formed under immense pressure in CNC-machined dies. This process aligns the steel’s grain flow with the tooth’s contours, creating inherent strength.

- Controlled Cooling & Heat Treatment: A multi-stage process including quenching and tempering establishes a hardened outer surface (typically 45-50 HRC) for wear resistance, paired with a tough, ductile core to absorb high-impact shocks without brittle fracture.

- Precision Machining: Critical mounting interfaces (e.g., the bore and locking groove) are machined to exact tolerances (IT8-IT9) to guarantee a secure, rattle-free fit with the adapter.

- Quality Inspection: Each batch undergoes dimensional checks, hardness testing, and metallographic analysis to ensure consistency.

2.2 Key Advantages of Forged Teeth

- Dense Microstructure: Forging eliminates internal voids and porosity common in cast teeth, leading to uniform hardness and superior structural integrity.

- Enhanced Impact Strength: The continuous grain flow provides exceptional resistance to chipping and breaking under sudden loads.

- Optimal Wear Life: Superior material density translates to longer service life in highly abrasive environments like rocky soil, quarried stone, and recycled materials.

- Reliable Performance: Predictable wear patterns and reduced risk of catastrophic failure ensure greater machine uptime.

3. Technical Specifications & Design Features

3.1 Material Science

- Steel Grade: Proprietary HELI boron-alloy steel (Equivalent to 35MnB, 40MnB).

- Hardness Profile: Surface hardness of 45-50 HRC with a graduated core hardness to manage impact.

- Metallurgical Properties: Fine, uniform martensitic/bainitic microstructure achieved through controlled heat treatment.

3.2 Ergonomic & Functional Design

- Penetration-Optimized Tip: Curvature and angle are engineered to reduce digging force and improve bucket filling efficiency.

- Reinforced Core Section: Extra material in high-stress areas (behind the tip and around the locking mechanism) prevents bending and premature failure.

- Precision Locking Interface: Machined to ensure a tight, secure fit with the adapter, eliminating unnecessary movement that causes accelerated wear.

4. HELI (DSWORD) Factory Capabilities: A Leader in Forging

As a top-quality forged bucket tooth manufacturer, our integrated facility ensures end-to-end quality control:

- Vertical Integration: We manage the entire process from raw material sourcing to final packaging, guaranteeing traceability and consistency.

- Modern Forging Presses: Utilization of high-tonnage mechanized presses for consistent and precise forging.

- Automated Heat Treatment Lines: Computer-controlled furnaces and quenching systems for repeatable metallurgical properties.

- Comprehensive QA/QC Lab: Equipped with spectrometers, hardness testers, and impact testers to validate every production batch against strict internal standards (ISO 9001 compliant).

- R&D Focus: Continuous development of new alloys and geometries to meet evolving market demands.

5. Value Proposition & Economic Benefits

Choosing HELI (DSWORD) forged teeth for your VOLVO EC950 is a strategic decision for cost management and productivity:

- Extended Wear Life: Directly reduces the frequency of tooth changes, lowering parts consumption and labor costs.

- Enhanced Productivity: Maintains sharp penetration and efficient bucket fill factors longer than inferior alternatives.

- Protection of Major Components: By wearing predictably and protecting the adapter/lip, costly repairs to the bucket structure are minimized.

- Superior Total Cost of Ownership (TCO): The combination of longer life, reduced downtime, and protected capital components delivers the lowest cost per cubic meter of material moved.

Conclusion

The VOLVO EC950 Forged Bucket Tooth (14727597TL) from HELI (DSWORD) represents the pinnacle of wear part engineering for ultra-class excavators. By combining sophisticated forging technology, advanced metallurgy, and precision manufacturing, we provide a product that delivers uncompromising performance, reliability, and value. Trust HELI (DSWORD) to be your partner in maximizing the productivity and profitability of your heavy equipment fleet.