VOLVO (14531515 / 71499210 / 4349518 / 9078675 / 9134126 / AT318030 / 9078675) EC700 Track Carrier Roller Assy / Upper Roller Assembly–Heavy duty construction machinery spare parts supplier and manufacturer / HELI CQCTRACK

Authentic-grade VOLVO EC700 track carrier roller (upper roller) assembly. Supplier & manufacturer HELI CQCTRACK delivers OEM-specified components (P/Ns: 14531515, 71499210, 4349518, 9078675, 9134126, AT318030) for heavy-duty construction machinery undercarriage systems.

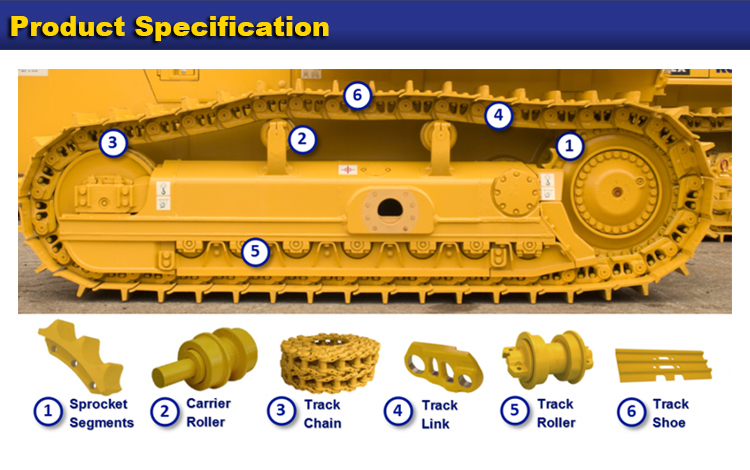

Technical Overview: The Track Carrier Roller (Upper Roller) Assembly in Heavy-Duty Undercarriages

In the engineered hierarchy of a crawler excavator’s undercarriage, such as that of the VOLVO EC700, the Track Carrier Roller Assembly—commonly termed the Upper Roller—performs a vital guiding and support function. Positioned along the upper section of the track frame, this component’s primary roles are to:

- Maintain Track Alignment: Guide the return path of the track chain, ensuring it remains properly seated and aligned as it travels from the front idler back to the drive sprocket.

- Manage Track Sag & Tension: Support the upper span of the track, helping to maintain correct tension and prevent excessive vertical whip or oscillation during high-speed travel and sudden directional changes.

- Reduce Frictional Wear: Minimize abrasive contact between the track chain links and the track frame itself, protecting both from premature wear.

For the VOLVO EC700, operating under severe loads, the carrier roller (referenced under part numbers 14531515, 71499210, 4349518, 9078675, 9134126, and AT318030) must be engineered for reliability with a focus on seal integrity and radial load capacity.

Engineering Specifications & Design of the EC700 Upper Roller Assembly

HELI CQCTRACK manufactures this assembly to precise OEM specifications, ensuring complete functional interchangeability and performance reliability.

- Robust Forged Core & Flange Design:

- The roller body is precision-forged from high-tensile carbon steel (e.g., 50Mn or 55# steel). This forging process provides superior metallurgical integrity, offering optimal resistance to deformation under continuous load and impact from track chain joints.

- It typically features a single, central guide flange. This design is optimized to engage with the track chain’s inner guiding guards, providing lateral stability without creating unnecessary drag or interference.

- Advanced Wear Surface Treatment:

- The outer circumferential running surface and the sides of the central flange undergo selective induction hardening. This process creates a deep, uniform hardened layer (typically 58-62 HRC) that maximizes resistance to abrasion from the track chain bushing surfaces, significantly extending service life.

- Sealed Lubrication & Bearing System:

- The assembly incorporates a high-capacity double-row tapered roller bearing or a specially designed cylindrical roller bearing set, chosen for its ability to handle high radial loads at various rotational speeds.

- Contaminant exclusion is critical. The assembly employs a multi-labyrinth seal configuration combined with high-performance nitrile rubber seals. This system creates a pressurized grease cavity, effectively blocking the entry of abrasive particulates and moisture, which are primary failure catalysts.

- Mounting & Integration:

- Designed for a bolt-on or press-fit installation onto the track frame’s carrier roller shaft. The internal bore and sealing surfaces are machined to fine tolerances to ensure a perfect fit, maintaining alignment and seal effectiveness.

HELI CQCTRACK: Integrated Manufacturer and Global Supplier

HELI CQCTRACK operates as both a primary manufacturer and a global supplier for heavy-duty construction machinery spare parts, offering a seamless chain from production to procurement.

Manufacturing & Quality Assurance Protocol:

- Vertical Manufacturing Integration: Complete in-house control over forging, machining, heat treatment, and assembly ensures consistency and traceability at every stage.

- Precision CNC Machining: Utilization of CNC turning centers and grinders guarantees exacting tolerances for outer diameter, flange profile, and critical sealing surfaces.

- Controlled Heat Treatment: Automated induction hardening lines with real-time temperature monitoring ensure repeatable and precise hardening depth and pattern on every unit.

- End-to-End Testing: Rigorous quality checks include:

- Material certification via spectrometry.

- Hardness and case depth verification.

- Dimensional analysis using CMM (Coordinate Measuring Machine) technology.

- Rotational resistance and seal integrity testing under simulated load conditions.

Value Proposition for Global Procurement

Sourcing the VOLVO EC700 Carrier Roller Assembly from HELI CQCTRACK provides strategic advantages for distributors, dealers, and large-scale end-users:

- OEM Specification Compliance: Components are engineered to match the exact dimensions, performance, and material specifications of the original VOLVO part numbers (14531515, 71499210, 4349518, 9078675, 9134126, AT318030), ensuring perfect fit and function.

- Manufacturer-Direct Supply: Eliminating intermediary layers ensures competitive pricing, reliable lead times, and direct technical support, enhancing supply chain efficiency.

- Durability-Focused Engineering: Enhancements in sealing technology and material selection aim to deliver a service life that aligns with or exceeds the wear characteristics of other major undercarriage components, promoting balanced system wear.

- Complete Undercarriage Solutions: As a full-range manufacturer, HELI CQCTRACK can supply matched sets of all undercarriage components (bottom rollers, idlers, sprockets, track chains), ensuring compatibility and performance synergy across the entire system.

Application and Maintenance Guidance

The VOLVO EC700 Track Carrier Roller Assembly is a critical wear component essential for:

- Scheduled preventive maintenance and undercarriage rebuilds.

- Corrective replacement of seized, leaking, or flange-damaged rollers.

- Performance restoration to reduce track noise, vibration, and irregular wear patterns.

Operational Best Practice: Regularly inspect upper rollers for smooth rotation and seal condition. Replacement is often recommended in conjunction with other roller sets to maintain uniform track tension and alignment, thereby optimizing the lifespan of the entire track system.

Conclusion

The Carrier Roller/Upper Roller Assembly is a fundamental contributor to the smooth operation and longevity of the VOLVO EC700′s undercarriage. HELI CQCTRACK, in its dual role as a certified manufacturer and global supplier, delivers this component with an unwavering commitment to precision engineering, material quality, and performance reliability. For industry professionals seeking a trustworthy source for heavy-duty construction machinery spare parts, HELI CQCTRACK provides an OEM-compatible solution engineered to withstand rigorous operational demands, ensuring machine availability and cost-effective equipment management.

Related accessories:

- Volvo EC700 Track shoes assembly 48Links 650MM

- Volvo EC700 Track link assembly Volvo 700 track chain 48Linsk

- Volvo EC700 Track shoes 650MM BERCO KM3201/650 HITACHI 2039879 HITACHI 4218739 ITM Z7670200N0650V SUMITOMO KUA0194 VOLVO 14522596

- Volvo EC700 track bolts of shoes HITACHI 3076901 HITACHI 4218740 ITM D7670000N15 VOLVO 14522607 VOLVO 14525773 VPI V4218740

- Volvo EC700 track Nuts of shoes HITACHI 3076904 HITACHI 4218741 ITM D7670000N17 VOLVO 14522606 VOLVO 14525774 VPI V4218741

- Volvo EC700 Carrier rollers Volvo 700 Top rollers BERCO HT75 FIAT-HITACHI 71499210 HITACHI 4349518 HITACHI 9078675 HITACHI 9134126 ITM C7670000M00 JOHN DEERE AT318030 TELCO-TATA 9078675 VOLVO 14531515 VPI V4349518V

- Volvo EC700 Sprocket 21Teeth 30Holes ITM R9365000M01 VOLVO 14532544 VOLVO VOE14532544

- Volvo EC700 front idlers ITM P9365400M00 VOLVO 14525744 VOLVO VOE14525744

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||