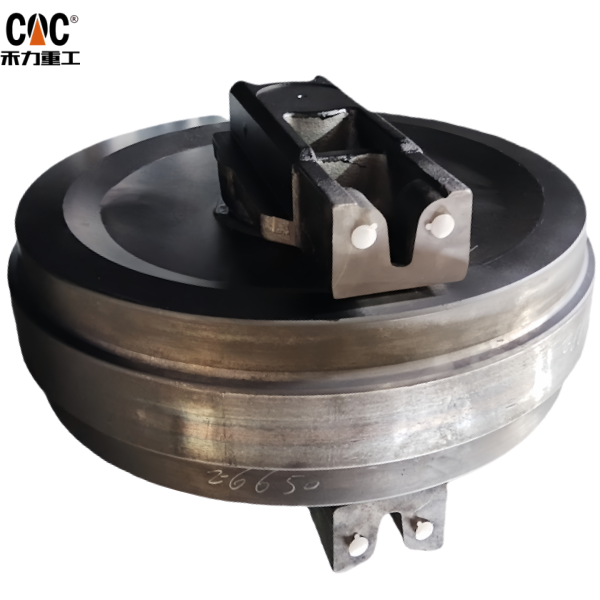

SDLG E6650 Front Idler Assembly | CQCTRACK-OEM&ODM Heavy-duty excavator Undercarriage Components Manufacturer and factory

The SDLG E6650 Track Front Idler Assembly is a fundamental and critical component within the undercarriage system of the SDLG E6650 crawler excavator. This specific assembly is manufactured by CQCTRACK, a recognized producer of aftermarket undercarriage parts. As the “front idler,” it is positioned at the forward end of the track frame, opposite the sprocket, and serves several essential mechanical functions:

- Track Guidance and Alignment: It provides a precise, hardened running surface for the track chain, guiding the track’s return path and ensuring proper alignment as it enters the sprocket and travels over the carrier and bottom rollers.

- Track Tension Adjustment: The front idler is not fixed; it is mounted on a sliding or yoke mechanism that can be adjusted forward or backward. This movement is crucial for setting the correct track sag, which is vital for optimal performance, preventing derailment, and minimizing wear on other undercarriage components.

- Load Distribution and Impact Absorption: It helps to absorb and distribute the initial impact loads when the track chain makes contact with the ground, especially when the machine traverses over obstacles.

2. Detailed Mechanical Structure and Component Breakdown

This assembly is a pre-lubricated, sealed, and non-serviceable unit designed for direct replacement. Its robust construction consists of the following integrated subsystems:

2.1. Idler Wheel

- Material: Fabricated from high-strength, low-alloy steel (e.g., Q345B or equivalent) for the core, with the running surface often reinforced.

- Manufacturing Process: The outer circumferential “tread” that contacts the track chain links is precision-machined. For enhanced durability, it is typically induction hardened or flame hardened to achieve a surface hardness of 50-55 HRC. This creates a wear-resistant layer that withstands constant abrasion from the track chain bushings.

- Design Feature: The idler features precisely machined guide flanges on both sides. These flanges are critical for containing the track chain’s bushings and preventing lateral derailment.

2.2. Central Hub and Bearing System

- Bearing Type: The core rotational mechanism relies on a set of large-diameter Tapered Roller Bearings. This bearing type is selected for its exceptional ability to withstand the significant combined radial loads (from the machine’s weight on the track) and axial (thrust) loads generated during excavator turning and side-slope operation.

- Bearing Mounting: The bearings are pre-adjusted, pre-lubricated, and press-fit into the idler’s central hub, which rotates around a stationary Idler Shaft (Spindle).

2.3. Stationary Spindle (Shaft)

- Material: Forged from high-tensile alloy steel (e.g., 42CrMo), heat-treated (quenched and tempered) to achieve high yield strength and fatigue resistance.

- Function: This is the non-rotating core of the assembly. It is a solid or hollow shaft that passes through the center of the idler and bearings. The ends of the spindle are machined with specific features (such as flats, threads, or smooth diameters) designed to interface securely with the track adjustment yoke and sleeve on the excavator’s track frame.

2.4. Advanced Multi-Labyrinth Sealing System

The longevity of the idler is predominantly determined by the effectiveness of its seals, which prevent lubricant leakage and contaminant ingress.

- Primary Seal: A Radial Lip Seal made of hydrogenated nitrile rubber (HNBR) for superior resistance to heat, abrasion, and oxidation. This seal acts against a hardened and ground seal washer.

- Secondary Seal / Dust Lip: An outward-facing auxiliary lip, often referred to as an excluder lip, designed to actively scrape off mud, clay, and other coarse contaminants before they penetrate the primary seal.

- Labyrinth Passage: The seal housing often incorporates a complex labyrinth path filled with grease. This creates a physical barrier that is extremely difficult for fine abrasive particles (like silica dust) to penetrate.

- Floating Face Seal Option: For extreme-duty applications, CQCTRACK may equip this assembly with a Mechanical Floating Face Seal, consisting of two highly polished, hardened steel rings forced together by O-rings, offering the highest level of sealing integrity in muddy and abrasive conditions.

2.5. Internal Lubrication

- Type: The internal cavity is packed with a high-viscosity, extreme-pressure (EP) Lithium Complex Grease containing Molybdenum Disulfide (MoS2). This grease is formulated to maintain a protective film under heavy shock loads and over a wide temperature range.

- Purpose: To provide continuous lubrication to the tapered roller bearings, reducing friction, dissipating operational heat, and preventing internal corrosion.

2.6. End Covers and Retainers

- Material: Pressed steel or machined carbon steel.

- Function: These covers are welded or bolted to the sides of the idler wheel. They serve to:

- Enclose and protect the internal bearing and seal assemblies from external damage.

- Provide a rigid structure for retaining the seals in place.

- Often act as the mounting surface for the outer components of the sealing system.

3. Key Performance and Compatibility Notes

- OEM Interchangeability: This CQCTRACK assembly is engineered to be a direct replacement for the original SDLG part, matching all critical dimensions, mounting interfaces, and performance specifications.

- Material Integrity: As an aftermarket specialist, CQCTRACK typically utilizes metallurgy and manufacturing processes (forging, heat treatment, precision machining) that meet or exceed OEM standards for durability and wear resistance.

- Failure Indicators: Common signs of a failing front idler include excessive lateral wobble, difficult rotation, visible grease leakage from the seals, abnormal wear patterns on the idler’s tread or flanges, and an inability to maintain proper track tension.

4. Conclusion

CQCTRACK’s Front Idler Assembly for the SDLG E6650 is a precision-engineered, heavy-duty component essential for the reliable and efficient operation of the excavator’s track system. Its robust construction—featuring a hardened idler wheel, a high-capacity tapered roller bearing system, a stationary alloy steel spindle, and an advanced multi-stage sealing mechanism—ensures long service life and reliable performance in the most demanding earthmoving and construction environments. Proper installation, including correct adjustment of track tension, is paramount to maximizing the operational lifespan of this vital undercarriage assembly.