Sanyi excavator SY700/750 idler group(61021657)china heavy duty excavator undercarriage part/OEM parts manufacture/idlers factory direct

SY700/750 idler group(61021657)for SANYI excavator heavy equipment.undercarriage parts manufacture-CQC/idlers factory direct

SANY SY700 Excavator Idlers – Heavy-Duty Track Rollers for 70-Ton Mining & Construction

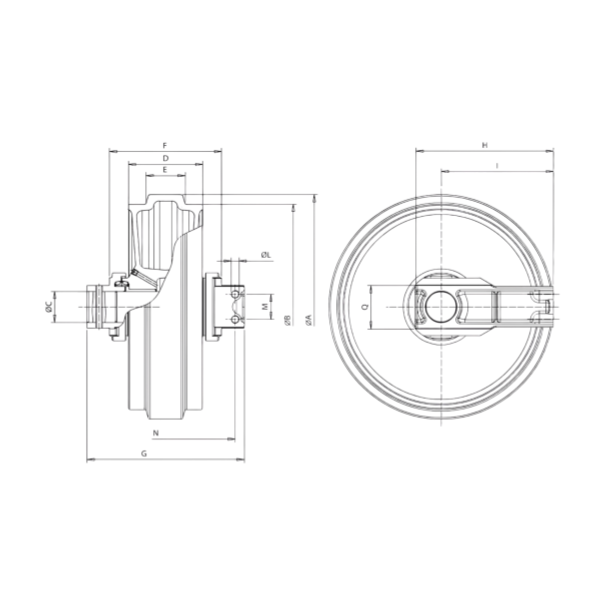

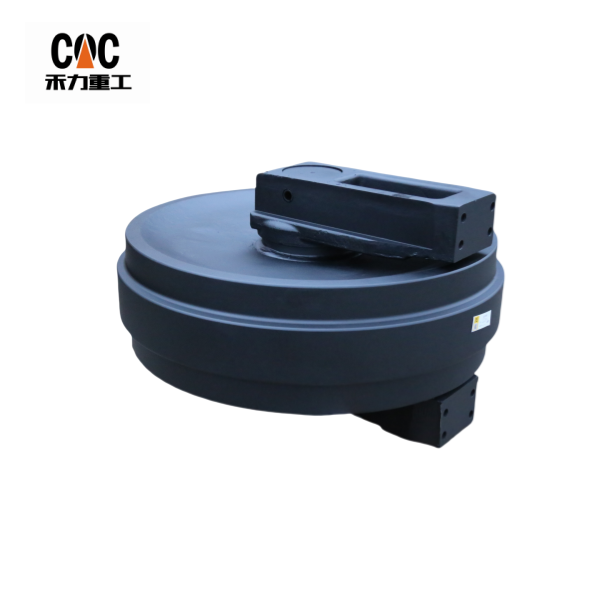

SANY SY700 idlers are precision-engineered undercarriage components designed for 70-ton class excavators, delivering reliable performance in demanding mining, quarrying, and large-scale construction applications. These heavy-duty rollers ensure optimal track alignment and load distribution for SY700 excavators operating in extreme conditions.

Key Features & Benefits

✔ High-Grade Alloy Steel Construction – Superior strength for 70-ton excavator loads

✔ Reinforced Double-Flange Design – Prevents track derailment in rough terrain

✔ Advanced Seal Technology – Multi-labyrinth + grease-purged seals for contamination protection

✔ OEM-Equivalent Quality – Direct replacement for SANY SY700/SY750 models

✔ Mining-Optimized – Hardened surfaces (HRC 50+) for extended abrasive wear resistance

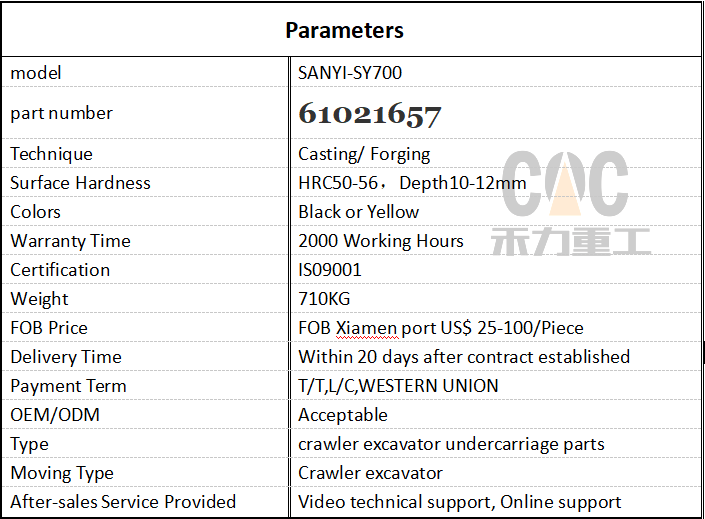

Technical Specifications

| Parameter | Specification |

|---|---|

| Dynamic Load Rating | 32,000 kg |

| Bearing System | Oversized tapered roller bearings |

| Flange Thickness | 28mm (reinforced) |

| Surface Hardness | HRC 50-55 (induction hardened) |

| Seal Type | Triple-lip + labyrinth design |

Compatible Models

- SANY SY700C

- SANY SY750H

- SANY SY700H (Hybrid models)

Why Choose SY700 Idlers?

✅ Extended Service Life – 30% longer wear life vs. standard idlers

✅ Reduced Vibration – Precision-balanced for smoother operation

✅ Easy Maintenance – Grease fittings for simplified servicing

✅ Cost Efficiency – Competitive pricing with OEM performance

When to Replace SY700 Idlers?

⚠ Flange wear exceeding 25% of original thickness

⚠ Visible cracks or spalling on rolling surfaces

⚠ Irregular track movement or jumping

⚠ Bearing noise/rough rotation

Maintenance Recommendations

- Daily: Remove debris accumulation between flanges

- Every 250 hrs: Check bearing play (max 1.5mm tolerance)

- Every 1,000 hrs: Replenish grease (using EP-2 lithium complex)

- Replace in Sets: Minimum 3 idlers for balanced performance

Available Configurations

- Standard Duty (SD): General earthmoving/construction

- Heavy Duty (HD): Extra-thick flanges for mining applications

- Tungsten Carbide Coated (TCC): For extreme abrasion resistance

Upgrade Options

▸ Wear Indicator Kits – Laser-etched depth markers

▸ Remote Monitoring – RFID-enabled wear sensors

▸ Arctic Packages – -40°C low-temperature seals

Need a Custom Solution? Provide:

- Machine serial number

- Current idler measurements

- Primary material handled (e.g., iron ore, granite, demolition debris)

Also available as part of complete SY700 undercarriage packages (sprockets + track chains + rollers).

For ultra-heavy mining applications, inquire about our SY700-XD Forged Idler Upgrade – combining forged durability with OEM fitment.

| For komatsu | ||||||||

| PC20-7 | PC30 | PC30-3 | PC30-5 | PC30-6 | PC40-7 | PC45 | PC45-2 | PC55 |

| PC120-6 | PC130 | PC130-7 | PC200 | PC200-1 | PC200-3 | PC200-5 | PC200-6 | PC200-7 |

| PC200-8 | PC210-6 | PC220-1 | PC220-3 | PC220-6 | PC220-7 | PC220-8 | PC270-7 | PC202B |

| PC220LC-6 | PC220LC-8 | PC240 | PC300 | PC300-3 | PC300-5 | PC300-6 | PC300-7 | PC300-7K |

| PC300LC-7 | PC350-6/7 | PC400 | PC400-3 | PC400-5 | PC400-6 | PC400lc-7 | PC450-6 | PC500-10 |

| PC600 | PC650 | PC750 | PC800 | PC1100 | PC1250 | PC2000 | ||

| D20 | D31 | D50 | D60 | D61 | D61PX | D65A | D65P | D64P-12 |

| D80 | D85 | D155 | D275 | D355 | ||||

| For HITACHI | ||||||||

| EX40-1 | EX40-2 | EX55 | EX60 | EX60-2 | EX60-3 | EX60-5 | EX70 | EX75 |

| EX100 | EX110 | EX120 | EX120-1 | EX120-2 | EX120-3 | EX120-5 | EX130-1 | EX200-1 |

| EX200-2 | EX200-3 | EX200-5 | EX220-3 | EX220-5 | EX270 | EX300 | EX300-1 | EX300-2 |

| EX300-3 | EX300-5 | EX300A | EX330 | EX370 | EX400-1 | EX400-2 | EX400-3 | EX400-5 |

| EX450 | ZAX30 | ZAX55 | ZAX200 | ZAX200-2 | ZAX330 | ZAX450-1 | ZAX450-3 | ZAX450-5 |

| ZX110 | ZX120 | ZX200 | ZX200 | ZX200-1 | ZX200-3 | ZX200-5g | ZX200LC-3 | ZX210 |

| ZX210-3 | ZX210-3 | ZX210-5 | ZX225 | ZX240 | ZX250 | ZX270 | ZX30 | ZX330 |

| ZX330 | ZX350 | ZX330C | ZX450 | ZX50 | zx650 | zax870 | ex1200-6 | ex1800 |

| For CATERPILLER | ||||||||

| E200B | E200-5 | E320D | E215 | E320DL | E324D | E324DL | E329DL | E300L |

| E320S | E320 | E320DL | E240 | E120-1 | E311 | E312B | E320BL | E345 |

| E324 | E140 | E300B | E330C | E120 | E70 | E322C | E322B | E325 |

| E325L | E330 | E450 | CAT225 | CAT312B | CAT315 | CAT320 | CAT320C | CAT320BL |

| CAT330 | CAT322 | CAT245 | CAT325 | CAT320L | CAT973 | cat365 | cat375 | cat385 |

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| For Sumitomo | ||||||||

| SH120 | SH120-3 | SH200 | SH210-5 | SH200 | SH220-3 | SH220-5/7 | SH290-3 | SH350-5/7 |

| SH220 | SH280 | SH290-7 | SH260 | SH300 | SH300-3 | SH300-5 | SH350 | SH60 |

| SH430 | sh480 | sh700 | ||||||

| For KOBELCO | ||||||||

| SK120-6 | SK120-5 | SK210-8 | SK210LC-8 | SK220 | SK220-1 | SK220-3 | SK220-5/6 | SK200 |

| SK200 | SK200 | SK200-3 | SK200-6 | SK200-8 | SK200-5/6 | SK60 | SK290 | SK100 |

| SK230 | SK250 | SK250-8 | SK260LC-8 | SK300 | SK300-2 | SK300-4 | SK310 | SK320 |

| SK330-8 | SK330 | SK350LC-8 | SK235SR | SK450 | SK480 | SK30-6 | sk460 | sk850 |

| For DAEWOO | ||||||||

| DH200 | DH220-3 | DH220 | DH220S | DH280-2 | DH280-3 | DH55 | DH258 | DH130 |

| DH370 | DH80 | DH500 | DH450 | /DH225 | ||||

| For HYUNDAI | ||||||||

| R60-5 | R60-7 | R60-7 | R80-7 | R200 | R200-3 | R210 | R210 | R210-9 |

| R210LC | R210LC-7 | R225 | R225-3 | R225-7 | R250 | R250-7 | R290 | R290LC |

| R290LC-7 | R320 | R360 | R954 | R450 | R800 | |||

| For KATO | ||||||||

| HD512 | HD1430 | HD 512III | HD 820III | HD820R | HD1430III | HD700VII | HD 1250VII | HD250SE |

| HD400SE | HD550SE | HD1880 | ||||||

| For DOOSAN | ||||||||

| DX225 | DX225LCA | DX258 | DX300 | DX300LCA | DX420 | DX430 | ||

| For VOLVO | ||||||||

| EC160C | EC160D | EC180B | EC180C | EC180D | EC210 | EC210 | EC210B | EC240B |

| EC290 | EC290B | EC240 | EC55 | EC360 | EC360B | EC380D | EC460 | EC460B |

| EC460C | EC700 | EC140 | EC140B | EC160B | ||||

| BULLDOZER | ||||||||

| For CATERPILLER | ||||||||

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| For komatsu | ||||||||

| D20 | D31 | D50 | D60 | D61 | D61PX | D65A | D65P | D64P-12 |

| D80 | D85 | D155 | D275 | D355 | ||||