SANY 61021657 SY870 Track Idler Assy-Guide Wheel Assy Heavy duty excavator Track Chassis component supplier&manufacturer–HELI(cqctrack)

Comprehensive Technical Description: SANY SY870 Excavator Track Idler Assembly/Guide Wheel Assembly (P/N: 61021657) – Supplier & Manufacturer: HELI (CQCTRACK)

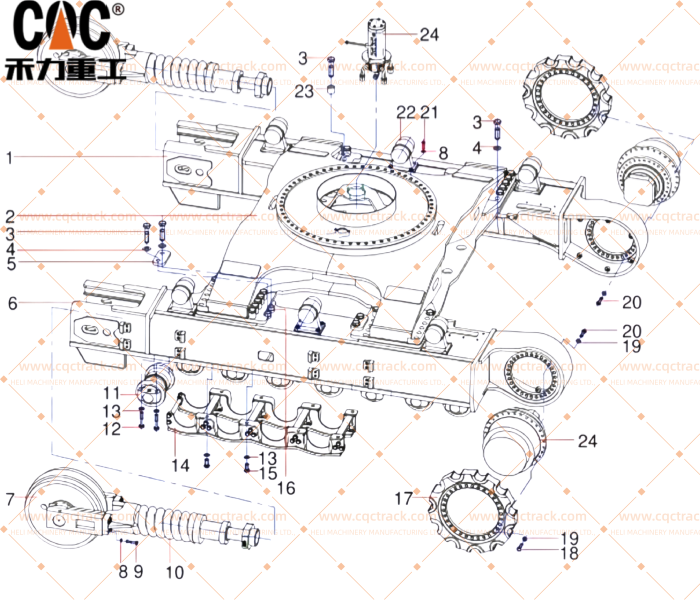

1. Component Identification and Functional Definition

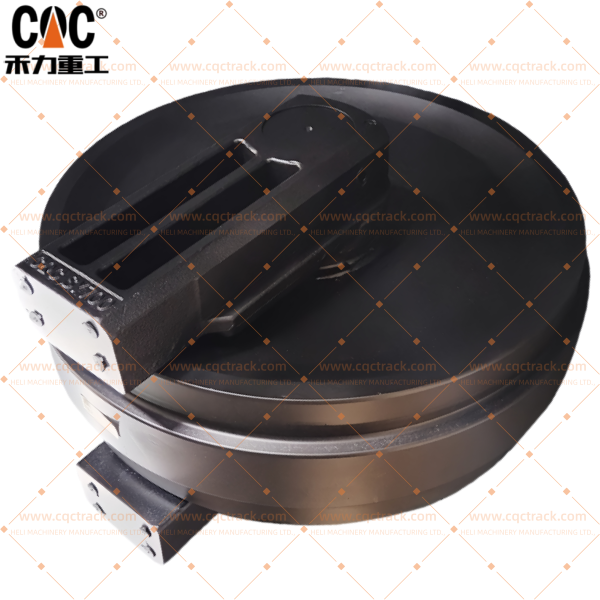

The Track Idler Assembly, also commonly termed Guide Wheel Assembly (P/N: 61021657), is a fundamental and critical load-bearing component within the track-type undercarriage system of the SANY SY870 heavy-duty excavator. As a primary supplier and manufacturer, HELI (branded as CQCTRACK) produces this assembly as a direct, precision-engineered replacement for the original SANY component. Positioned at the front of the track frame opposite the sprocket, the idler serves as the forward guiding and tensioning element for the entire track chain, playing a pivotal role in undercarriage integrity and machine mobility.

2. Primary Functions and Operational Mechanics

The SANY SY870 Track Idler Assembly performs several indispensable functions:

- Track Chain Guidance and Alignment: It provides a smooth, hardened rotating surface that guides the track chain’s links, ensuring perfect alignment as the chain enters and travels along the track frame, preventing derailment.

- Track Tension Adjustment: The idler is mounted on a sliding or adjustable bracket connected to a hydraulic or screw-type tensioning mechanism. This allows operators to apply precise forward force to the track chain, maintaining optimal tension—critical for preventing excessive slap, reducing wear, and ensuring efficient power transfer.

- Impact Absorption and Load Distribution: It absorbs and distributes the initial impact loads as the track chain rolls onto the undercarriage during travel, especially over uneven terrain, protecting other components from shock.

- Structural Interface: It acts as the forward mounting point for the track gauge, maintaining the correct distance between the two parallel track chains.

3. Detailed Structural Composition and Advanced Engineering

The heavy-duty idler assembly from HELI (CQCTRACK) for the SANY SY870 is a robust, multi-component system engineered for maximum durability:

- Idler Wheel Body: Fabricated from high-grade, forged alloy steel (e.g., 40Mn2, 50Mn). The outer circumferential running surface is precision-machined and undergoes advanced induction hardening or carburizing to achieve a deep, uniform hardness (typically HRC 55-62), providing exceptional resistance to abrasive wear from track link contact.

- Integral Hub & Shaft Assembly: Features a high-tensile steel shaft, often flange-mounted, which is interference-fitted or welded into the idler wheel hub. The shaft’s bearing journals are precision-ground and hardened.

- Heavy-Duty Bearing System: Employs large-diameter, high-capacity Tapered Roller Bearings or Spherical Roller Bearings. These are selected for their superior ability to handle the extreme radial loads from machine weight and significant axial (thrust) loads generated during turning and side-slope operation.

- Multi-Stage Sealing System: Incorporates a triple-labyrinth seal combined with nitrile rubber (NBR) or Viton sealing rings and dust lips. This creates multiple barriers against the ingress of abrasive contaminants (fine sand, rock dust) and water/mud. The seal cavity is pre-filled with high-performance, lithium-complex EP grease.

- Adjustment Housing & Bushings: The assembly interfaces with the track frame’s sliding guide through hardened steel bushings or wear rings, which are designed as replaceable items to protect the core adjustment mechanism from wear.

- Lubrication Points: Features standard SAE grease fittings for periodic servicing of both the idler bearings and the adjustment slide bushings.

4. Technical Specifications and Manufacturing Standards (HELI/CQCTRACK)

- Dimensional & Interchangeability Compliance: Manufactured to exact OEM geometric specifications for the SANY SY870, including outer diameter, width, hub bore, bolt circle diameter (BCD), and overall width—ensuring perfect fit and function.

- Load Capacity: Engineered to withstand the gross operating weight of the SY870 excavator (approximately 70+ tons) and the dynamic impact loads encountered in mining and heavy excavation.

- Material & Process Certification: Utilizes certified raw materials with traceable heat numbers. Heat treatment processes are computer-controlled and validated to meet ISO 6336 or similar standards for mechanical properties.

- Performance Testing: Each assembly or batch undergoes rigorous testing for rotational resistance, seal integrity under pressure wash simulation, and dimensional conformity.

5. Manufacturer Profile: HELI (CQCTRACK) as a Source

HELI, through its dedicated undercarriage division CQCTRACK, is a principal global supplier of undercarriage components, operating as both a full-service manufacturer and a supply chain partner. For the SANY 61021657 Idler Assembly, HELI provides:

- Vertical Manufacturing Integration: Complete in-house control from material selection, forging, machining, heat treatment, assembly, to painting.

- Advanced Production Technology: Utilizes CNC lathes, vertical machining centers, automated induction hardening lines, and robotic welding for consistency.

- Quality Assurance Infrastructure: Employs spectrometers for material analysis, CMMs for dimensional verification, and dedicated test rigs for seal and bearing performance validation.

- Supply Chain Role: Acts as a reliable bulk supplier to distributors and direct-to-end-user channels, offering components that meet or exceed OEM performance specifications at a competitive value.

6. Application, Compatibility, and Maintenance

- Primary Application: SANY SY870 Crawler Excavator.

- System Integration: Installed on the front of each track frame, connected to the recoil and tensioning mechanism.

- Wear Indicators & Maintenance: Service life is extended through regular lubrication and cleaning. Wear is measured on the outer diameter of the idler rim and the flange thickness. Excessive wear leads to poor track alignment, uneven track link wear, and potential derailment. The adjustable bushing/slide area must also be inspected for excessive play.

- Replacement Consideration: Idler wear should be assessed in conjunction with the track chain (links & bushings), sprocket, and carrier rollers to ensure balanced undercarriage wear and avoid accelerated wear on new components.

Conclusion

The SANY 61021657 SY870 Track Idler/Guide Wheel Assembly manufactured and supplied by HELI (CQCTRACK) is a mission-critical component built to endure the severe operational demands of a large mining-class excavator. It exemplifies engineering precision through its hardened wear surfaces, robust bearing and sealing systems, and strict adherence to OEM specifications. As a source manufacturer, HELI/CQCTRACK provides a reliable, high-performance alternative that ensures the SANY SY870 maintains optimal track tension, alignment, and overall undercarriage efficiency, thereby supporting maximum machine availability and productivity in the most challenging environments.