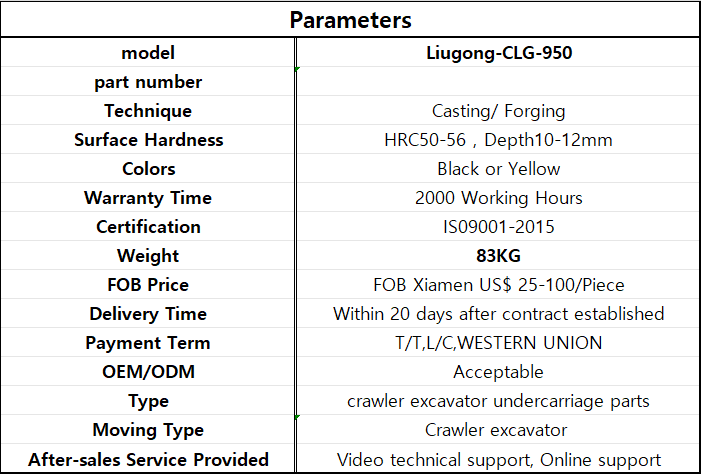

Liugong excavator-CLG-950 final drive sprocket ass’y/OEM supply/high quality spare parts manufacture/China excavator sprocket factory

Liugong excavator-CLG-950 final drive sprocket ass’y/OEM supply/high quality spare parts manufacture/China excavator sprocket factory

Excavator Drive Sprocket: Complete Guide

The drive sprocket (also called final drive sprocket) is a critical component that transfers power from the excavator’s final drive motor to the track chain, enabling movement. Here’s everything you need to know:

1. Functions of a Drive Sprocket

✔ Transmits Power – Converts motor rotation into track movement.

✔ Engages Track Links – Teeth mesh with track chain bushings to propel the machine.

✔ Supports Machine Weight – Works with rollers and idlers to distribute load.

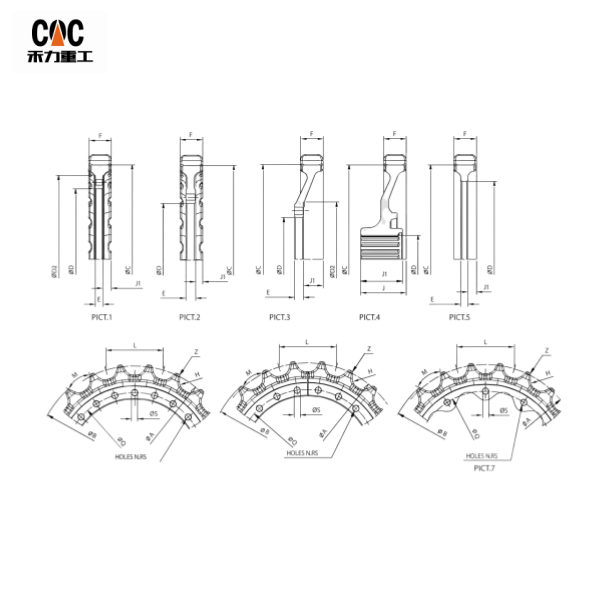

2. Types of Drive Sprockets

| Type | Description |

|---|---|

| Segmented Sprocket | Made of replaceable sections (cost-effective for repairs). |

| Solid (One-Piece) Sprocket | Traditional welded/forged design (full replacement required). |

| Bolt-On Sprocket | Attached to the final drive hub (easier replacement). |

| Double-Pitch Sprocket | Used in heavy-duty applications for longer wear life. |

3. Signs of a Worn-Out Drive Sprocket

⚠ Pointed or Hooked Teeth (indicates excessive wear)

⚠ Track Slippage or Jumping (poor engagement with chain)

⚠ Grinding/Clicking Noises (misalignment or damaged teeth)

⚠ Uneven Wear on One Side (track tension or alignment issue)

⚠ Cracks or Broken Teeth (requires immediate replacement)

4. Drive Sprocket vs. Idler vs. Carrier Roller

| Component | Function |

|---|---|

| Drive Sprocket | Drives the track chain (powered by the final drive). |

| Front Idler | Guides and tensions the track (non-powered). |

| Carrier Roller | Supports track weight and prevents sagging. |

5. Replacement & Maintenance Tips

✔ Check Track Chain & Bushings – Worn chains accelerate sprocket wear.

✔ Replace in Pairs (both left & right sprockets for balanced performance).

✔ Use OEM or Premium Aftermarket Brands (Berco, cqc, Komatsu, CAT).

✔ Inspect Final Drive Seals – Leaks can damage the sprocket hub.

✔ Maintain Proper Track Tension (too tight/loose causes premature wear).

| KOMATSU | HITACHI | CAT | KOBELCO | SUMITOM | DAEWOO | HYUNDAY |

| PC30 | EX55 | E305.5/E55 | SK55 | SH60 | DH35 | R60/R60-5/-7 |

| PC40 | EX60 | E306 | SK60-3 | SH120 | DH55 | R80 |

| PC45 | ZAX70/EX70 | E70B/C307 | SK60-5 | SH120A3 | DH60 | R130/R150 |

| PC50/55 | EX100 | E70B Bilateral | SK60-8 | SH200/SH280 | DH80 | R200/225-7 |

| PC60-6 | ZAX130 | E312/C100 | SK100 | SH220/340 | DH130/150 | R220-9 |

| PC60-7 | EX200-1 | E320/E200B | SK140 | SH300 | DH220 | R250-9 |

| PC100 | EX200-2/-5 | E324 | SK200 | SH350 | DH220-9 | R275-9 |

| PC200 | EX300 | E325/325 | SK270 | SH350 large | DH300 | R290/R305 |

| PC300/-5 | ZAX330 | E330 | SK330/SK350 | SH450 | DH360/400 | R370 |

| PC400/PC450 | EX400/DX380 | E345 | SK380-10 | SH460 | DH500 | R485-9 |

| PC650-8 | EX550 | E350 | SK450/460 | SH700 | DH700 | R500 |

| PC650-5/750 | ZAX650 | E375 | SK850 | R800 | ||

| PC800 | ZAX750 | E385 | ||||

| PC1000 | ZAX870 | E390 | ||||

| PC1250 | EX1100 | |||||

| PC2000 | EX1200-6 | |||||

| EX1800 | ||||||

| EX3000 | ||||||

| DOOSAN | VOLOV | KATO | KUBOTA | CASE | 福田 | SANY |

| DX60 | EC55B | HD250/HD307 | KX35 | CX35 | FT60 | SY75/65 |

| DX60-9 | EC80 | HD450 | KX60/50/55 | CX75 | FT85 | SY215 |

| DX800 | EC140 | HD770/HD700 | KX85 | CX360 | FT150 | SY335/365 |

| VOL140 | HD1023 | CX800 | FT220 | SWZ216D(SY395) | ||

| YUCHAI | EC210 | HD1250/1430 | Yanmar | FT350 | SY405 | |

| CY35 | VOL210 (New) | HD1638 | YM55 | ISHIKAWA ISLAND | FT480 | SY485 |

| CY60 | EC220D | YM75 | IHI50/60 | SY550 | ||

| CY85 | VOL290 | JCB | IHI100 | SY650 | ||

| CY135 | VOL360 | JCB8056 | 竹内 | IHI50/60 | SY750 | |

| EC460 | JCB220 | TB150 | IHI135 | SY850 | ||

| EC700 | JCB360 | TB160 | SY950 | |||

| EC900 | JCB550 | TB171/175 | ||||

| 夏工 | SUNWARD | LIUGONG | 龙工 | LIEBHERR | XCMG | Other |

| XG8360 | SWE50 (Bilateral) | CLG906 | LG6065 | R914/LBH | XG370 | JD360 |

| XG8330 | SWE Smart 50 | CLG150 | LG65 | R924/LBH | XG700 | 宇通/ET360 |

| XG8250/8220 | SWE Smart 60/65 | CLG200/925 | LG6150 | R944/LBH | XG900 | 彭浦 60 |

| XG815 | SWE70 | CLG936 | LG6235 | R944SME/LBH | XG1200 | 阿特拉斯 |

| XG808 | SWE22 | CLG945 | LG6285 | R974/LBH | XG2000 | |

| XG806 | SWE220 | CLG950 | LG6360 | R984 | XG3000 | |

| SWE250 | CLG970 | LG6490 | R9100 | |||

| 詹阳 | SWE280 | CLG990 | ||||

| ZY200 | SWE470 | |||||

| ZY300 |