KOMATSU KM2224 / 2093000012 / 2093000013 / 2093000014 PC800 Track Idler Wheel Assembly – Heavy duty construction machinery parts original manufacturer and supplier / HELI CQCTRACK

Comprehensive technical specifications for the KOMATSU KM2224 PC800 Track Idler Wheel Assembly (Part #2093000012, 2093000013, 2093000014). Explore original-grade manufacturing by HELI CQCTRACK, a specialist in heavy-duty construction machinery undercarriage parts.

Content:

Introduction: The Critical Role of the Idler in Ultra-Class Excavator Undercarriages

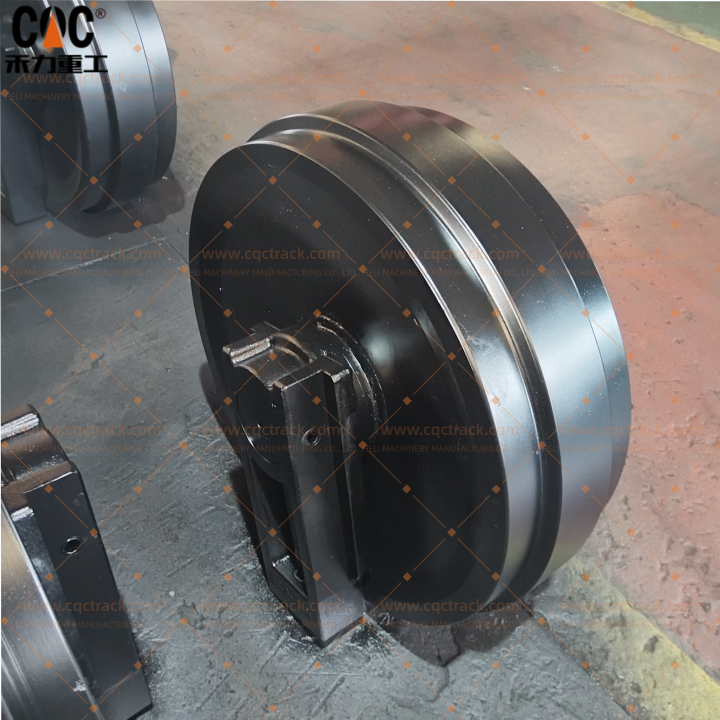

In the domain of heavy-duty mining and construction, where equipment like the KOMATSU PC800 excavator operates under extreme loads and continuous cycles, the undercarriage is engineered as a high-integrity system. The Track Idler Wheel Assembly stands as a fundamental pivot point in this system. Designated under specification KM2224 and part numbers :2093000012, 2093000013, and 2093000014, this component is far more than a simple guide wheel. It is a sealed, load-bearing structural unit responsible for maintaining track chain alignment and tension, while simultaneously absorbing monumental shock loads and resisting relentless abrasive wear. Its performance is inextricably linked to machine stability, track life, and overall operational cost-effectiveness.

Technical Specification Analysis: KOMATSU PC800 Idler Assembly KM2224

The KM2224 specification encompasses a heavy-duty idler assembly designed explicitly for the demanding service parameters of the PC800 platform. The variance in part numbers (KM2224, 2093000012, 2093000013, 2093000014) typically indicates revisions, specific manufacturing lots, or subtle design updates over the machine’s production life, all maintaining core functional interchangeability within strict OEM tolerances.

- Engineering Design & Functional Mechanics:

- Frontal Pivot & Tensioning Hub: The idler serves as the forward mounting point for the track recoil spring and adjuster cylinder assembly. It translates hydraulic or grease pressure from the adjuster into precise linear movement, setting the critical track chain sag.

- Dual-Duty Load Path: It vertically supports a significant portion of the machine’s weight as the track enters the ground contact zone and acts as the first line of defense against impact forces from obstructions.

- Precision Guidance: The integrated, robust flanges on either side of the idler wheel provide rigid lateral containment for the track chain, preventing derailment during high-stress slewing and travel maneuvers on uneven terrain.

- Component Architecture & Material Science:

- Forged Alloy Steel Core: The idler wheel body is manufactured from high-tensile, heat-treatable alloy steel forgings (e.g., AISI 4140/42CrMo). This ensures optimal strength-to-weight ratio and superior fatigue resistance under cyclical bending stresses inherent in mining applications.

- Advanced Wear Surface Engineering: The running surface that contacts the track chain bushings undergoes case hardening via carburizing or deep induction hardening. This process creates a hardened layer (typically 58-63 HRC) with exceptional resistance to abrasive grooving, while preserving a tough, ductile core to withstand impact loads.

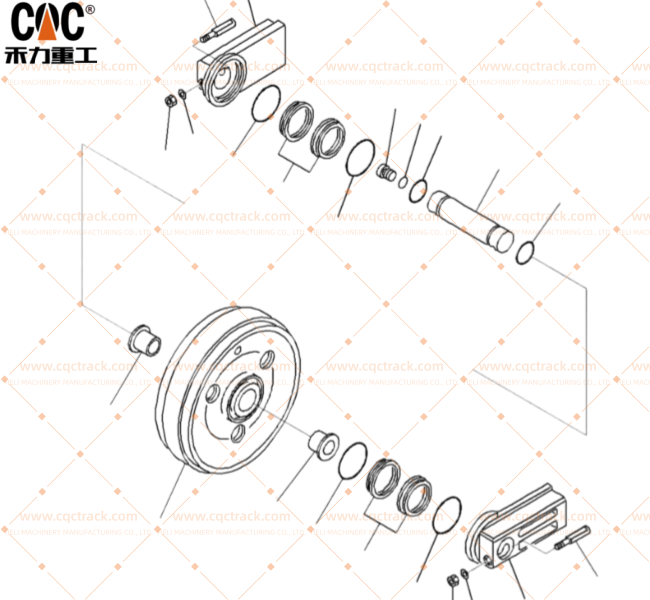

- Sealed Bearing Cartridge System: At its heart, the assembly incorporates a large-diameter, multi-row tapered roller bearing or specially configured roller bearing pack. This is permanently lubricated and protected by a multi-stage sealing system, often comprising radial lip seals, floating face seals, and labyrinth pathways to create an impenetrable barrier against particulate contamination and moisture ingress.

- Precision-Machined Interfaces: The idler shaft and bushing housings are machined to micron-level tolerances to ensure perfect alignment with the track roller frame, minimizing eccentric run-out and uneven wear.

- Failure Mode & Durability Considerations: For a machine of the PC800′s class, idler failure modes are amplified:

- Bearing Spalling/Seizure: Primarily caused by seal failure leading to lubricant contamination or loss.

- Flange Fatigue Fracture: Results from extreme lateral shock loads or misalignment.

- Wheel Grooving & Profile Loss: Accelerated by running with an overly worn track chain, leading to inefficient track roll and increased power consumption.

HELI CQCTRACK: As an Original-Grade Manufacturer and Global Supplier

HELI, operating under the brand CQCTRACK, is a vertically integrated manufacturer specializing in OEM-equivalent heavy-duty undercarriage components. For critical parts like the KOMATSU KM2224 PC800 Idler Assembly, they replicate not just dimensions but the material properties, heat treatment specifications, and performance benchmarks of the original.

Manufacturing Protocol & Quality Assurance:

- Specification-First Approach: Production begins with exhaustive analysis of OEM specifications, including material grade, hardness profiles, and dimensional tolerances for all relevant part numbers (2093000012, 2093000013, 2093000014).

- Full-Process Control: The manufacturing journey encompasses closed-die forging under hydraulic presses, normalizing for stress relief, rough and finish CNC machining, controlled atmosphere heat treatment, and final assembly in a clean environment.

- Critical Process Expertise:

- Carburizing/Carbonitriding: Used to achieve the deep, hard case required on the wheel’s running surface.

- Precision Grinding: Post-heat-treatment grinding ensures final dimensional accuracy and surface finish on sealing surfaces and bearing journals.

- Seal & Bearing Sourcing: Integration of international standard (ISO) or OEM-specified bearing sets and high-temperature, abrasion-resistant seal kits.

- Rigorous Validation Testing: Each batch undergoes spectrochemical analysis, ultrasonic testing for internal forging defects, Charpy V-notch impact testing for core toughness, hardness mapping, and dimensional inspection via CMM (Coordinate Measuring Machine).

Value Proposition in the Global Supply Chain:

HELI CQCTRACK positions itself as a strategic supplier by offering:

- Direct OEM Replacement: Guaranteed geometric and functional interchangeability for the PC800 undercarriage system.

- Engineering Integrity: Focus on replicating the material science and mechanical properties that define the part’s durability, not just its shape.

- Supply Chain Resilience: Providing a reliable, quality-assured alternative source for these essential wear parts, reducing downtime risks for global mining and heavy earthmoving operations.

Operational Maintenance & Replacement Guidance

Proactive management of the KOMATSU PC800 Track Idler Assembly (KM2224) is vital for cost control.

- Scheduled Inspection: Regularly monitor for oil leakage (seal failure), abnormal lateral play, visible cracks on flanges or wheel body, and asymmetric wear patterns.

- System-Wear Management: The idler’s condition must be evaluated as part of the complete Undercarriage Wear Package. Replacing a heavily grooved idler in conjunction with a new track chain and sprocket is a standard best practice to ensure synchronized wear and extended component life.

- Professional Installation: Emphasis on correct installation procedures, including proper cleaning of the track frame saddle, correct adjustment of the recoil mechanism, and adherence to specified torque values for mounting hardware.

Conclusion

The KOMATSU (KM2224 ,2093000012, 2093000013, 2093000014) Track Idler Wheel Assembly for the PC800 excavator exemplifies the high-engineering standards required for ultra-class machinery. HELI CQCTRACK, through its dedicated manufacturing philosophy and rigorous quality systems, establishes itself as a capable source for original-grade undercarriage components. For fleet managers and maintenance engineers operating in the most demanding sectors, partnering with a technical manufacturer like HELI provides a viable pathway to maintaining equipment integrity, ensuring operational availability, and achieving optimal lifecycle cost for monumental assets like the Komatsu PC800.

| For komatsu | ||||||||

| PC20-7 | PC30 | PC30-3 | PC30-5 | PC30-6 | PC40-7 | PC45 | PC45-2 | PC55 |

| PC120-6 | PC130 | PC130-7 | PC200 | PC200-1 | PC200-3 | PC200-5 | PC200-6 | PC200-7 |

| PC200-8 | PC210-6 | PC220-1 | PC220-3 | PC220-6 | PC220-7 | PC220-8 | PC270-7 | PC202B |

| PC220LC-6 | PC220LC-8 | PC240 | PC300 | PC300-3 | PC300-5 | PC300-6 | PC300-7 | PC300-7K |

| PC300LC-7 | PC350-6/7 | PC400 | PC400-3 | PC400-5 | PC400-6 | PC400lc-7 | PC450-6 | PC500-10 |

| PC600 | PC650 | PC750 | PC800 | PC1100 | PC1250 | PC2000 | ||

| D20 | D31 | D50 | D60 | D61 | D61PX | D65A | D65P | D64P-12 |

| D80 | D85 | D155 | D275 | D355 | ||||

| For HITACHI | ||||||||

| EX40-1 | EX40-2 | EX55 | EX60 | EX60-2 | EX60-3 | EX60-5 | EX70 | EX75 |

| EX100 | EX110 | EX120 | EX120-1 | EX120-2 | EX120-3 | EX120-5 | EX130-1 | EX200-1 |

| EX200-2 | EX200-3 | EX200-5 | EX220-3 | EX220-5 | EX270 | EX300 | EX300-1 | EX300-2 |

| EX300-3 | EX300-5 | EX300A | EX330 | EX370 | EX400-1 | EX400-2 | EX400-3 | EX400-5 |

| EX450 | ZAX30 | ZAX55 | ZAX200 | ZAX200-2 | ZAX330 | ZAX450-1 | ZAX450-3 | ZAX450-5 |

| ZX110 | ZX120 | ZX200 | ZX200 | ZX200-1 | ZX200-3 | ZX200-5g | ZX200LC-3 | ZX210 |

| ZX210-3 | ZX210-3 | ZX210-5 | ZX225 | ZX240 | ZX250 | ZX270 | ZX30 | ZX330 |

| ZX330 | ZX350 | ZX330C | ZX450 | ZX50 | zx650 | zax870 | ex1200-6 | ex1800 |

| For CATERPILLER | ||||||||

| E200B | E200-5 | E320D | E215 | E320DL | E324D | E324DL | E329DL | E300L |

| E320S | E320 | E320DL | E240 | E120-1 | E311 | E312B | E320BL | E345 |

| E324 | E140 | E300B | E330C | E120 | E70 | E322C | E322B | E325 |

| E325L | E330 | E450 | CAT225 | CAT312B | CAT315 | CAT320 | CAT320C | CAT320BL |

| CAT330 | CAT322 | CAT245 | CAT325 | CAT320L | CAT973 | cat365 | cat375 | cat385 |

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| For Sumitomo | ||||||||

| SH120 | SH120-3 | SH200 | SH210-5 | SH200 | SH220-3 | SH220-5/7 | SH290-3 | SH350-5/7 |

| SH220 | SH280 | SH290-7 | SH260 | SH300 | SH300-3 | SH300-5 | SH350 | SH60 |

| SH430 | sh480 | sh700 | ||||||

| For KOBELCO | ||||||||

| SK120-6 | SK120-5 | SK210-8 | SK210LC-8 | SK220 | SK220-1 | SK220-3 | SK220-5/6 | SK200 |

| SK200 | SK200 | SK200-3 | SK200-6 | SK200-8 | SK200-5/6 | SK60 | SK290 | SK100 |

| SK230 | SK250 | SK250-8 | SK260LC-8 | SK300 | SK300-2 | SK300-4 | SK310 | SK320 |

| SK330-8 | SK330 | SK350LC-8 | SK235SR | SK450 | SK480 | SK30-6 | sk460 | sk850 |

| For DAEWOO | ||||||||

| DH200 | DH220-3 | DH220 | DH220S | DH280-2 | DH280-3 | DH55 | DH258 | DH130 |

| DH370 | DH80 | DH500 | DH450 | /DH225 | ||||

| For HYUNDAI | ||||||||

| R60-5 | R60-7 | R60-7 | R80-7 | R200 | R200-3 | R210 | R210 | R210-9 |

| R210LC | R210LC-7 | R225 | R225-3 | R225-7 | R250 | R250-7 | R290 | R290LC |

| R290LC-7 | R320 | R360 | R954 | R450 | R800 | |||

| For KATO | ||||||||

| HD512 | HD1430 | HD 512III | HD 820III | HD820R | HD1430III | HD700VII | HD 1250VII | HD250SE |

| HD400SE | HD550SE | HD1880 | ||||||

| For DOOSAN | ||||||||

| DX225 | DX225LCA | DX258 | DX300 | DX300LCA | DX420 | DX430 | ||

| For VOLVO | ||||||||

| EC160C | EC160D | EC180B | EC180C | EC180D | EC210 | EC210 | EC210B | EC240B |

| EC290 | EC290B | EC240 | EC55 | EC360 | EC360B | EC380D | EC460 | EC460B |

| EC460C | EC700 | EC140 | EC140B | EC160B | ||||

| BULLDOZER | ||||||||

| For CATERPILLER | ||||||||

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| For komatsu | ||||||||

| D20 | D31 | D50 | D60 | D61 | D61PX | D65A | D65P | D64P-12 |

| D80 | D85 | D155 | D275 | D355 | ||||