HYUNDAI Track Chassis Components 81QE-13010 Track Idler Assembly-Big undercarriage manufactured by HELI(cqctrack)

Technical Specification & Engineering Report: HYUNDAI 81QE-13010 Heavy-Duty Track Idler Assembly

Document Control

- Report No.: HELI-TS-2025-81QE13010

- Component: Track Idler Assembly (Front Idler)

- OEM Model: HYUNDAI R-Series (R1200, R1250LC-9 etc.)

- OEM Part No.: 81QE-13010

- Manufacturer: HELI Machinery Manufacturing Co., Ltd. (Brand: CQCTRACK)

- Classification: Heavy-Duty Undercarriage Component

1. Executive Summary & Product Positioning

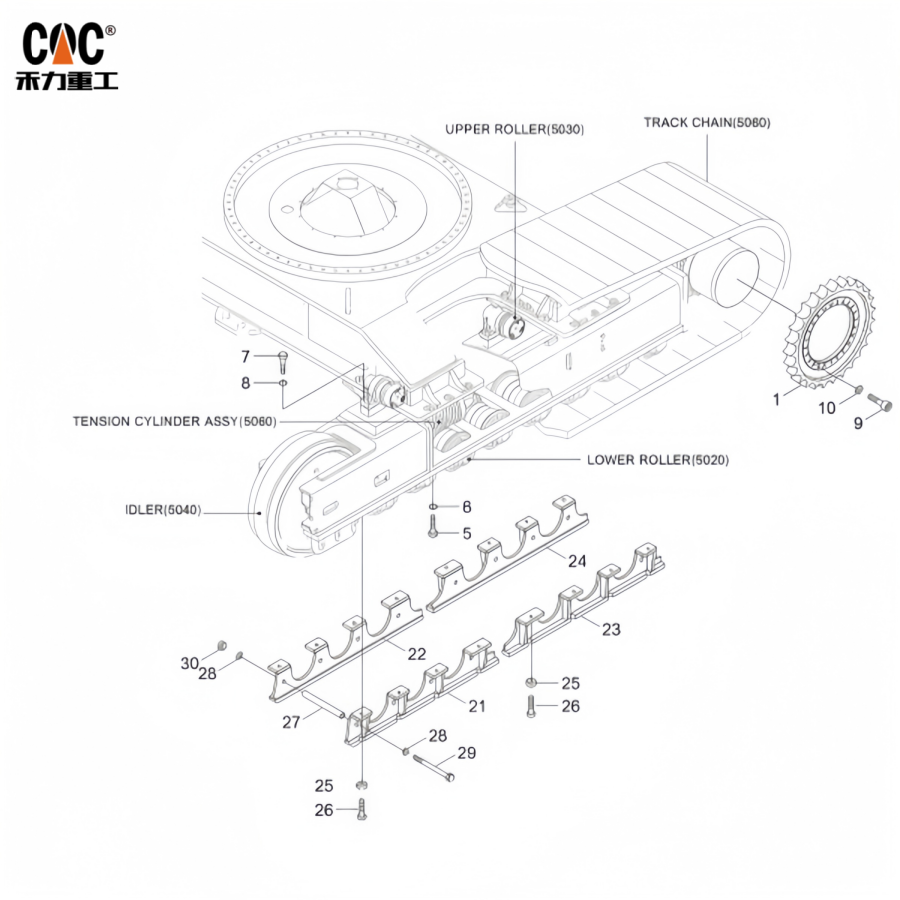

This document details the engineering specifications and manufacturing pedigree of the HYUNDAI 81QE-13010 Track Idler Assembly, produced by HELI Machinery (CQCTRACK). As a critical load-bearing and tensioning component within the crawler undercarriage system, this idler assembly is engineered for the demanding operational profiles of HYUNDAI’s 8-130 ton class excavators. Leveraging over two decades of specialized undercarriage manufacturing expertise, HELI delivers an ODM/OEM equivalent assembly that meets or exceeds original performance specifications through advanced material science, precision machining, and rigorous quality validation. This idler is designed to provide exceptional service life, reliability, and total cost of ownership (TCO) in severe applications including quarrying, construction, and general excavation.

2. Functional Anatomy & System Role of the Track Idler

The Track Idler, positioned at the front of the crawler frame opposite the sprocket, performs three primary mechanical functions:

- Track Guidance & Alignment: It guides the track chain, maintaining correct lateral alignment during travel and steering to prevent derailment.

- Track Tensioning: As part of the recoil and tensioning system (via the adjuster cylinder), it takes up slack in the track chain, ensuring optimal pitch engagement with the sprocket and proper ground contact of the track shoes.

- Load Transmission: It supports a portion of the machine’s weight and absorbs forward and reverse impact loads from ground irregularities.

The 81QE-13010 is a sealed and lubricated assembly, comprising the idler wheel, internal bearings/bushings, a hardened shaft, end covers, and a multi-stage sealing system, pre-assembled for direct bolt-on replacement.

3. Core Engineering & Manufacturing Specifications by HELI (CQCTRACK)

HELI’s manufacturing philosophy for the 81QE-13010 is grounded in vertical integration and failure-mode analysis, ensuring each sub-component is optimized for durability.

3.1 Material Selection & Metallurgy

| Component | Material Specification | Engineering Justification |

|---|---|---|

| Idler Wheel Body | Forged 50Mn or 55Mn High-Carbon Manganese Steel. | Provides an optimal balance of high hardenability for surface wear resistance and excellent core toughness to withstand repeated impact loads without cracking. |

| Shaft | Alloy Steel 40Cr, precision ground and chrome-plated at seal contact areas. | 40Cr steel offers superior tensile and yield strength to resist bending moments. Chrome plating reduces friction and adhesive wear against seal lips, a critical factor in extending seal life. |

| Bushing / Bearing | High-Density Sintered Bronze Bushing (Oil-Impregnated) or Tapered Roller Bearing (Application-specific). | Sintered bronze provides self-lubrication, conformability, and excellent shock load absorption. Bearing configurations offer high radial load capacity for specific duty cycles. |

| Seal Wear Rings | Hardened Steel (HRC 55+). | Acts as a sacrificial wear surface, protecting the main idler body and shaft from abrasion, thereby extending the overall assembly’s life. |

3.2 Critical Manufacturing Processes

- Forging: The idler wheel is hot-forged to refine the steel grain structure, enhancing its mechanical strength and fatigue resistance compared to cast alternatives.

- Heat Treatment: The idler wheel rim undergoes computer-controlled induction hardening to achieve a surface hardness of 56-60 HRC with a controlled case depth of 8-12mm. This is followed by tempering to relieve stresses and maintain core toughness (~35-40 HRC).

- Machining: All critical surfaces are finished on CNC lathes and grinders. The bore for the bushing/bearing, the sealing surfaces, and the mounting interfaces are held to tight tolerances (IT7-IT8) to ensure perfect concentricity and seal performance.

- Assembly & Sealing: The assembly is conducted in a clean environment. The sealing system typically incorporates a multi-labyrinth design paired with a double-lip radial seal (NBR or FKM/Viton®) and a floating metal wear ring. This triple-defense system effectively excludes mud, sand, and water while retaining grease.

4. Performance Data & Quality Assurance

HELI’s quality regimen ensures every 81QE-13010 idler assembly delivers consistent, reliable performance.

4.1 Key Performance Indicators (KPIs):

- Radial Runout: < 0.5 mm (ensures smooth track operation and reduces vibration).

- Seal Leakage Test: Subjected to air pressure test to verify seal integrity before greasing.

- Rotational Torque: Consistent and within specified range, confirming proper bearing/bushing pre-load and lubrication.

- Static Load Rating: Designed to withstand the full recoil force of the tensioning system and dynamic impacts.

4.2 Quality Assurance Protocol:

- Incoming Material Inspection: Spectrographic analysis of steel chemistry.

- In-Process Inspection: Dimensional checks after key machining operations.

- Final Inspection: 100% inspection of critical dimensions, hardness verification, and surface finish.

- Testing: Sample units from each batch undergo extended rotational endurance and seal contamination tests.

- Certification: Manufactured under an ISO 9001:2015 certified quality management system. Material certifications (Mill Certs) per EN 10204 3.1 are available.

5. Installation, Maintenance & Compatibility Guidelines

- Installation: Always follow the OEM (HYUNDAI) service manual procedure.

- Safely block the machine and release track tension.

- Remove the old idler assembly, noting the number of shims for tension adjustment.

- Clean the idler mounting brackets on the track frame thoroughly.

- Install the new HELI idler assembly, re-using the correct shim pack to achieve the initial alignment.

- Reconnect the tensioning cylinder, re-tension the track to specification, and check track sag.

- Maintenance: While the assembly is “sealed for life,” it should be inspected regularly (every 250 service hours). Look for:

- Fluid Leakage: Grease around the shaft ends.

- Abnormal Wear: Asymmetric wear on the idler rim or flanges.

- Impaired Rotation: A stiff or non-rotating idler.

- Compatibility: The 81QE-13010 is designed as a direct replacement for specified HYUNDAI R-series excavators. Always verify the machine model and serial number against the OEM parts catalog or consult HELI’s technical sales team for confirmation.

6. Value Proposition & Supply Chain

6.1 Total Cost of Ownership (TCO) Advantage:

The HELI (CQCTRACK) 81QE-13010 idler assembly offers a superior TCO compared to non-specialist aftermarket parts:

- Extended Service Life: Premium materials and deep hardening delay wear-out, extending replacement intervals.

- Reduced Downtime: High reliability minimizes unplanned failures and associated productivity losses.

- Component Protection: A robust idler maintains proper track alignment and tension, protecting adjacent expensive components like track chains and sprockets from accelerated wear.

6.2 Supply from HELI / CQCTRACK:

As a factory-direct manufacturer, HELI provides:

- Technical Support: Engineering data and application assistance.

- Flexible Logistics: Options for FOB, CIF, or DAP incoterms, with export-standard packaging.

- Traceability: Full batch traceability from raw material to finished good.

Disclaimer: This engineering report is for informational purposes. Specifications are subject to change due to continuous product improvement. The end-user is responsible for verifying the suitability of this component for their specific application and machine.