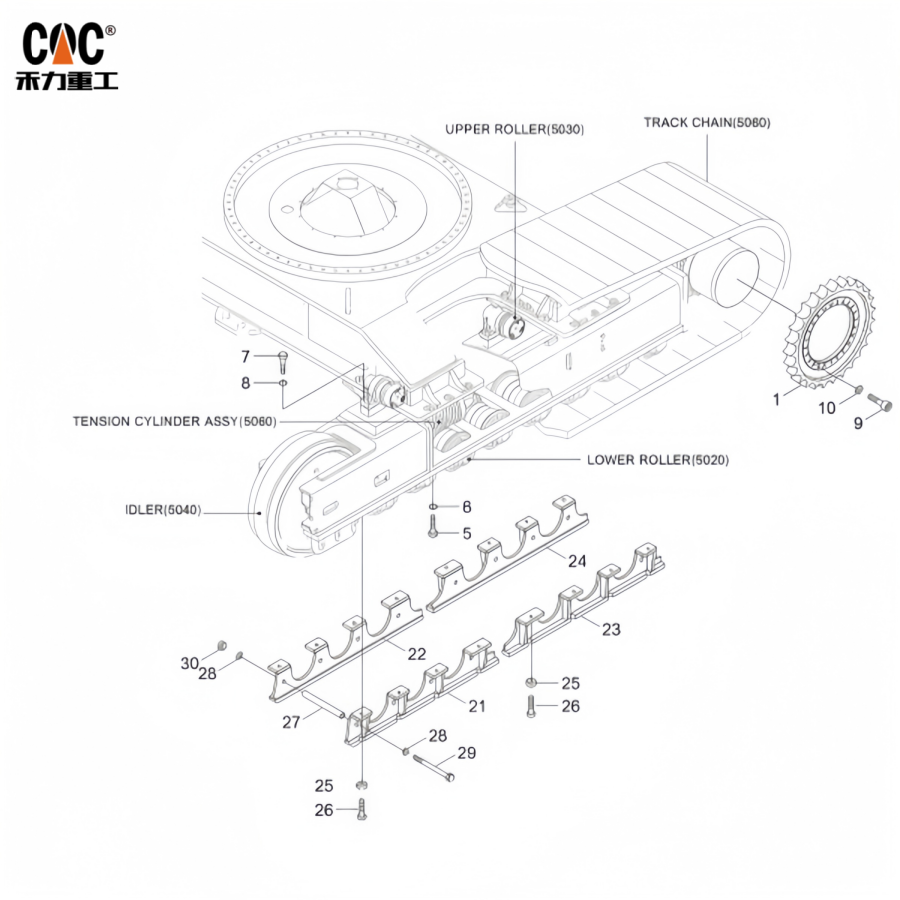

HYUNDAI 81QE11010 R1250 Track Botoom Roller Assembly/Heavy duty crawler excavator Chassis Component manufacturer-HELI MACHINERY MANUFACTURING CO.,LTD(CQC TRACK)

Engineering White Paper: The HYUNDAI R1250 81QE11010 Track Bottom Roller Assembly: A Synthesis of Certified Precision and Severe-Duty Engineering by HELI MACHINERY MANUFACTURING CO., LTD.

Document Identifier: TWP-CQC-HMMCL-81QE11010-01

Date of Publication: December 2025

Classification: Public Technical Specification

1.0 Executive Summary: The Certification-Engineered Advantage

This technical document delineates the engineering philosophy, manufacturing rigor, and performance specifications of the HYUNDAI 81QE11010 Track Bottom Roller Assembly for the R1250-class heavy-duty crawler excavator, as architected and produced by HELI MACHINERY MANUFACTURING CO., LTD. (branded as CQC TRACK). In an industry where component failure equates to catastrophic downtime, our offering transcends the paradigm of a mere replacement part. It embodies a Certification-Engineered Product, where the stringent, systemized protocols of the China Quality Certification (CQC) framework are intrinsically woven into every stage of its lifecycle—from metallurgical sourcing to final audit.

The core thesis of this assembly is that true reliability in severe-duty applications is not an accidental outcome but a verifiable result of a controlled, audited process. HELI MACHINERY operates under a multi-layered certification umbrella, holding both ISO 9001:2015 quality system recognition and multiple, specific CQC product certification certificates (e.g., CQC17704176145). This dual foundation mandates a factory quality assurance system encompassing everything from supplier vetting and key component validation to precise production equipment maintenance and comprehensive record-keeping spanning at least 24 months. For the R1250 operator, this translates to an undercarriage component whose documented consistency and durability are engineered, manufactured, and perpetually verified, delivering minimized total cost of ownership through maximized mean time between failures.

2.0 Deconstructing the Certification-Engineered Manufacturing Protocol

The value of the 81QE11010 assembly is rooted in the enforceable discipline of the CQC factory inspection and supervision system. The following table maps how these mandatory procedures translate directly into tangible component quality and traceability.

| CQC Factory Quality Assurance Requirement | Implementation in 81QE11010 Production | Engineering & Reliability Benefit for the End-User |

|---|---|---|

| Supplier Selection & Management Program | Rigorous vetting and approval of alloy steel forgings and specialty seal material suppliers. | Ensures raw material integrity, the fundamental determinant of fatigue life and impact resistance. |

| Key Components/Materials Inspection & Verification | Incoming inspection of forged roller blanks and sintered alloy bushing stock against certified specifications. | Prevents sub-standard materials from entering production, a direct application of CQC’s “first responsibility” principle. |

| Regular Confirmation Testing for Key Components | Periodic sampling and laboratory testing of material hardness, microstructure, and chemical composition. | Provides ongoing, objective validation that material properties remain within specified engineering limits. |

| Production Equipment Maintenance System | Scheduled preventive maintenance for CNC lathes, induction hardening units, and grinding machines. | Guarantees machining precision and heat-treatment consistency, batch after batch. |

| Routine & Confirmation Testing Procedures | 100% dimensional inspection; sampling for dynamic load testing and seal integrity validation. | Every unit is verified for fit, and sample performance is statistically confirmed against type-test standards. |

| Control of Non-Conforming Products | Systematic quarantine and analysis of any part failing to meet any inspection checkpoint. | Ensures only components fulfilling all specifications are assembled, safeguarding final product integrity. |

| Internal Quality Audit & Management Review | Scheduled internal audits and management reviews of the entire quality management system. | Drives continuous improvement and ensures the system’s sustained effectiveness. |

| Comprehensive Record Retention (≥24 months) | Full digital traceability for each production batch: material certs, heat-treatment logs, inspection results. | Provides unparalleled transparency and supports warranty or failure analysis with hard data. |

3.0 Technical Exegesis: Component-Level Engineering Under Certification

The CQC framework provides the “how”; advanced engineering defines the “what.” The 81QE11010 assembly is a masterclass in targeted material science and mechanical design.

3.1 Roller Body & Flange: Forged and Hardened for Abrasion Dominion

- Material: The core is a forged blank of 40SiMnTi or 50Mn high-tensile, fine-grain alloy steel. This selection prioritizes exceptional hardenability and core toughness over common lower-grade steels.

- Process: Subjected to computer-controlled, deep-case induction hardening. The process parameters are meticulously documented as per CQC-mandated process control records.

- Specification: Achieves a surface hardness of 58-62 HRC with a controlled effective case depth of 8-12 mm, transitioning to a tough core of 38-42 HRC. This deep, glass-hard surface is engineered to withstand extreme abrasive wear from pulverized rock and soil, while the ductile core absorbs the high-impact shocks inherent to mining and quarrying, preventing catastrophic brittle fracture.

3.2 The Sealing Axis: A Tribological and Containment System

- Shaft: Fabricated from case-hardened 40Cr or 20CrMnTi alloy steel, precision-ground to a mirror finish (Ra ≤ 0.4 μm). This minimizes friction and wear on the sealing interface, a critical factor for long-term integrity.

- Bushing: Utilizes a high-density, oil-impregnated sintered copper alloy. This material offers excellent conformability and load-bearing capacity, with the embedded lubricant providing a secondary emergency lubrication source.

- Sealing System: Employs a multi-stage, pressure-adaptive labyrinth seal. This system integrates a primary floating metal wear ring to deflect gross abrasives, a multi-lip nitrile rubber seal energized by a patented spring design, and a grease-purged labyrinth. It is designed to maintain integrity under the high static pressure of deep mud immersion and the dynamic pressure of high-speed track rotation.

3.3 Assembly & Final Validation: The Final Gate

The assembly is conducted in a controlled environment. The cavity is purged and filled with a lithium complex, extreme-pressure (EP) grease specified for a wide temperature range (-30°C to +150°C). Prior to dispatch, each unit undergoes a final operational test for rotational smoothness and seal integrity. This final check is a mandatory part of the CQC-defined “routine inspection”, closing the loop on production quality control.

4.0 Compliance, Interchangeability, and Performance Commitment

- OEM Compatibility: The 81QE11010 is engineered for direct, unmodified interchangeability with the HYUNDAI R1250 undercarriage system. All critical interface dimensions—shaft diameter, bolt hole circular pitch, overall width, and flange profile—are held to stringent tolerances.

- Performance Warranty: The component is backed by a performance warranty that is underwritten by its certified manufacturing process. The extensive documentation required by CQC supervision provides an objective basis for this confidence.

- Global Supply Assurance: HELI MACHINERY MANUFACTURING CO., LTD. supports global logistics with export-standard packaging and full certification documentation, including material test certificates and factory inspection reports, facilitating seamless cross-border procurement.

5.0 Conclusion: Redefining Value Through Verifiable Process

The HYUNDAI R1250 81QE11010 Track Bottom Roller Assembly from HELI MACHINERY (CQC TRACK) represents a definitive evolution from a commodity spare part to a process-guaranteed engineering component. Its superiority is not merely claimed but is structurally enforced through the rigors of CQC product certification and factory supervision. This certification-engineering approach ensures that every unit delivered is a direct descendant of a rigorously type-tested and approved design, manufactured within a quality system subject to annual surveillance and unannounced audits.

For the discerning equipment manager, the value proposition is clear: invest in a component whose extended service life and unwavering reliability are engineered into its very DNA and validated by one of the most structured quality assessment regimes in manufacturing. This results in the ultimate metric for heavy machinery: maximized machine availability and minimized cost per operating hour.

Disclaimer: Specifications and designs are subject to continuous improvement. It is recommended to verify the exact machine model and serial number range for compatibility before procurement. The CQC certification information is based on the manufacturer’s public credentials and standard CQC protocols