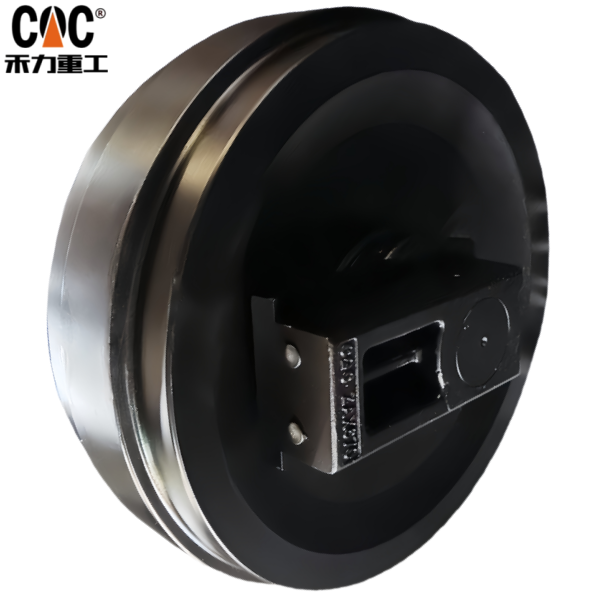

HITACHI ZAX670 ZAX690 Track Idler Wheel Assembly (P/N: YA00026685, YA00014544,4658412) | Mining-Grade Undercarriage Parts Manufacturer & Supplier | HELI (CQCTRACK)

Professional manufacturer HELI (CQCTRACK) supplies OEM-quality track idler wheel assemblies (P/N YA00026685, YA00014544,4658412) for HITACHI ZAX670 & ZAX690 excavators. Engineered for extreme mining conditions with superior wear resistance, sealed lubrication, and direct factory support. Custom ODM/OEM solutions available.

Product Overview: Heavy-Duty Track Idler Wheel Assembly

The Track Idler Wheel Assembly (Original Part Numbers: YA00026685, YA00014544,4658412) is a mission-critical frontline component in the undercarriage system of HITACHI ZAX670 and ZAX690 series large crawler excavators. Manufactured to exacting OEM specifications by HELI (CQCTRACK), a leading global specialist in undercarriage components, this assembly serves as the primary forward guide and tensioning anchor for the track chain. In demanding applications such as mining, quarrying, and large-scale earthmoving, the idler’s performance directly impacts machine stability, track life, and overall operational uptime.

Engineered for Extreme Mining & Quarry Environments

Mining and quarry operations present the most severe challenges for undercarriage components: constant exposure to high-impact loads, highly abrasive materials (e.g., iron ore, granite, basalt), continuous shock from uneven rock surfaces, and pervasive dust and slurry. The HELI (CQCTRACK) idler assembly for HITACHI ZAX670/690 is specifically designed to withstand these conditions:

- Ultra-High Abrasion Resistance: The idler wheel rim is fabricated from premium forged alloy steel (e.g., 50Mn, 60Si2Mn) and undergoes a proprietary deep induction hardening process. This creates a hardened surface layer (HRC 58-62) with a deep effective case depth, ensuring extended service life against the grinding wear of track bushings even in silica-rich environments.

- Superior Impact & Shock Load Capacity: The robust design and tough core material (HRC 30-40) provide exceptional resistance to cracking and deformation from direct rock strikes and high-energy impacts during travel over blasted rock piles.

- Contaminant Exclusion System: A state-of-the-art triple-labyrinth seal combined with heavy-duty radial lip seals forms an impervious barrier. This multi-stage sealing is packed with high-temperature, waterproof lithium-complex grease, effectively preventing the ingress of fine rock dust, slurry, and moisture—the primary causes of premature bearing failure.

Detailed Technical Specifications & Performance Features

- Precision Engineering: Manufactured to exact HITACHI OEM dimensional tolerances for outer diameter (OD), total width, flange height, bore size, and bolt pattern, guaranteeing perfect fit and alignment with the track frame and chain.

- Core Components:

- Wheel Body: Forged alloy steel, deep hardened.

- Shaft & Flange: High-tensile steel, precision machined and ground.

- Bearing System: High-capacity tapered roller bearings or spherical roller bearings selected for optimal radial and axial load capacity during turns and side-loading.

- Seals: Multi-component, labyrinth-style, designed for high-pressure washdown survival.

- Wear Rings/Bushings: Hardened and replaceable, protecting the idler housing and track frame.

- Load Rating: Designed to exceed the dynamic load requirements of the 60-70 ton excavator class (ZX670/690) under full-load operational stress.

Manufacturer’s Strength: HELI (CQCTRACK) Professional Capabilities

HELI (CQCTRACK) operates as a vertically integrated manufacturer with full control over the production chain, ensuring quality and cost-effectiveness:

- OEM/ODM Expertise: Serves as both an OEM supplier and an Original Design Manufacturer (ODM). We can manufacture to supplied samples, drawings (2D/3D), or exact OEM part numbers.

- Complete In-House Production: Our process encompasses material forging, CNC machining, computerized heat treatment, automated assembly, and rigorous testing. We utilize advanced CNC lathes, vertical machining centers, and induction hardening lines.

- Quality Management System: Certified to ISO 9001:2015 standards. Each production batch is subject to material spectroscopy, hardness testing (superficial and core), dimensional verification via CMM, and seal performance testing.

- R&D & Customization: Our engineering team supports full customization for special applications, including material upgrades, seal enhancements, or dimensional adjustments for modified equipment.

Maintenance Guidelines & Service Life Optimization

- Routine Inspection: Regularly check for abnormal wear patterns on the rim and flanges, excessive lateral play, and any signs of seal damage or grease leakage.

- Proper Lubrication: Adhere to machine service intervals for the idler’s grease fittings. Use recommended high-quality, extreme-pressure grease to replenish the internal cavity and purge contaminants.

- Track Tension Management: Always maintain correct track tension as per the operator’s manual. Over-tensioning increases idler bearing load; under-tensioning causes excessive track slap and premature wear.

- Systematic Replacement: For optimal undercarriage economy, assess idler wear in conjunction with the track chain (pins & bushings), sprocket, and carrier rollers. Replacing severely worn components in matched sets prevents accelerated wear on new parts.

Compatibility & Direct Application

- Primary Compatible Models: This assembly is a direct replacement for the HITACHI ZAX670LC, ZAX670LCH, ZAX690LCH and equivalent variant excavators.

- OEM Part Number Interchange: Directly replaces HITACHI part numbers YA00026685 and YA00014544. Always verify machine serial number for final confirmation.

Factory Direct Sales & Customization Support

- Direct-from-Factory Pricing: By eliminating intermediaries, HELI (CQCTRACK) offers competitive pricing for high-volume orders while maintaining premium quality.

- Sample & Drawing-Based Manufacturing: We welcome customer-provided original samples or detailed technical drawings for precise quotation and manufacturing. Our ODM service is ideal for bespoke requirements or proprietary designs.

- Flexible Ordering & Logistics: We support flexible MOQs and provide professional export packaging, with reliable global shipping and logistics support via FOB, CIF, or DDP terms.

Comprehensive After-Sales Service & Warranty

- Technical Support: Our engineering team provides pre-sales technical consultation and after-sales support for installation and troubleshooting.

- Product Warranty: All our idler wheel assemblies are backed by a standard warranty against manufacturing defects, covering materials and workmanship.

- Spare Parts Availability: We maintain strategic stock of core components and can provide matching wear parts (e.g., seals, bushings) to support long-term maintenance needs.

Conclusion

The HITACHI YA00026685 / YA00014544 Track Idler Wheel Assembly from HELI (CQCTRACK) represents the optimal synergy of mining-tough durability, precision OEM engineering, and direct manufacturer value. Designed to endure the most punishing environments, it ensures reliable performance, maximizes undercarriage component life, and minimizes unscheduled downtime for your HITACHI ZAX670 and ZAX690 excavators. As your trusted partner, we combine manufacturing excellence with flexible customization and dedicated support to meet your exact undercarriage parts requirements.

Contact us today for a competitive quotation, technical data sheets, or to discuss your custom ODM/OEM project.