HITACHI EX1200-6 Track Idler Wheel Assembly 4696615 / YA00035320PS / YA00035319 | Mining & Heavy Excavator Undercarriage Component | Expert Manufacturer HELI CQCTRACK

Professional-grade HITACHI EX1200-6 track idler wheel assembly (P/N: 4696615 / YA00035320PS / YA00035319). Engineered for mining and severe-duty applications by undercarriage expert manufacturer HELI CQCTRACK. Featuring forged construction, extreme-duty sealing, and OEM interchangeability.

Technical Introduction: The Idler Wheel in Large Mining Excavator Undercarriages

For ultra-class mining excavators like the HITACHI EX1200-6, the Track Idler Wheel Assembly represents a fundamental pivot point within the track chassis system. Positioned at the fore of the track frame, it performs three critical functions under extreme static and dynamic loads: (1) guiding and aligning the track chain with precision, (2) absorbing and dissipating massive shock loads from direct ground impact, and (3) serving as the adjustable interface for proper track tension via the recoil mechanism. Its failure can lead to catastrophic track derailment and significant downtime. The assembly referenced under part number 4696615 is therefore engineered not for general construction, but for the relentless, high-cycle demands of mining and major earthmoving operations.

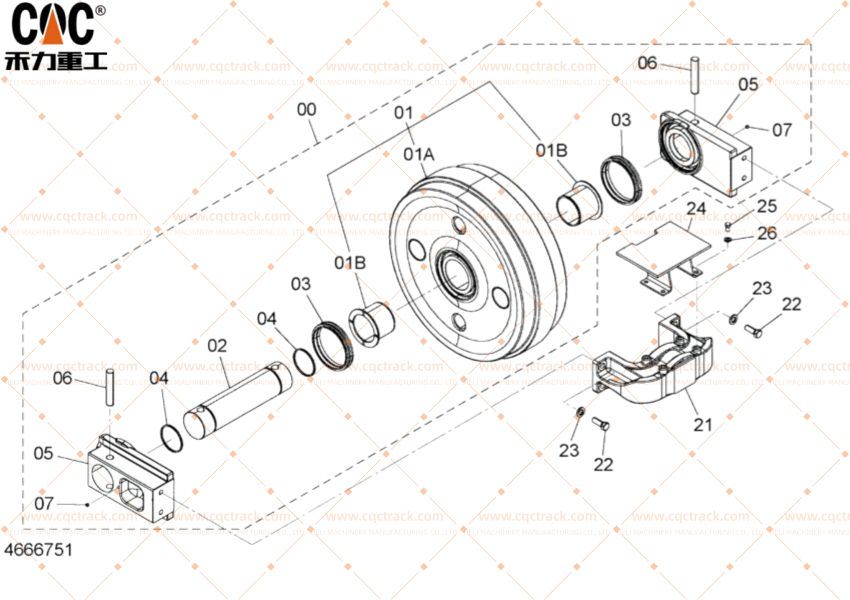

Engineering Specifications & Design Philosophy for P/N: 4696615;4666751

HELI CQCTRACK’s manufacturing of this component adheres to a philosophy of exceeding baseline specifications to address known failure points in severe environments.

- Cast Alloy Steel Construction & Metallurgical Integrity:

- The idler body is hot-forged from high-alloy steel (e.g., 40CrMnMo or similar), selected for its exceptional yield strength and fracture toughness. This provides the necessary structural integrity to withstand the immense bending moments and impact forces encountered by a machine of this class without plastic deformation.

- Optimized Flange Geometry & Hardfacing Application:

- The double-flange design is precisely profiled to match the EX1200-6 track chain. Beyond standard hardening, the flange root and leading edges—areas prone to high-stress concentration and abrasive wear from track side-guards—often receive automated hardfacing deposits. This applies a layer of premium wear-resistant alloy, dramatically extending the service life before flange hooking occurs.

- Multi-Stage, Pressurized Sealing System:

- The bearing cavity is protected by a tiered sealing assembly specifically designed for high-contaminant environments. This typically integrates:

- A primary heavy-duty radial face seal with a robust spring.

- A secondary labyrinth-style grease chamber that acts as a contaminant buffer zone.

- An outer dust guard or floating seal as a final barrier.

- The system is pre-filled with a high-temperature, high-pressure lithium-complex grease, creating positive internal pressure to expel invasive particulates.

- The bearing cavity is protected by a tiered sealing assembly specifically designed for high-contaminant environments. This typically integrates:

- High-Capacity Bearing & Internal Spacer System:

- The assembly utilizes extra-large, double-row tapered roller bearings or custom-configured spherical roller bearings. These are paired with precision-ground spacer sleeves to ensure perfect internal alignment and preload, eliminating axial play and distributing loads evenly across the entire bearing raceway.

HELI CQCTRACK: Expertise in Heavy-Duty Chassis Component Manufacturing

HELI CQCTRACK distinguishes itself as an expert manufacturer through specialized engineering focus and process validation tailored to large excavator components.

- Application-Specific Engineering: Designs are validated using FEA (Finite Element Analysis) to simulate stress distribution under maximum load scenarios, allowing for strategic reinforcement in high-stress zones of the idler body and hub.

- Advanced Forging & Heat Treatment: Controlled forging parameters ensure optimal grain flow. The heat treatment regimen involves normalizing after forging to relieve stress, followed by quenching and tempering to achieve the required core toughness, and finally induction hardening of wear surfaces to a specified depth profile.

- Precision Machining & Quality Gates: Critical interfaces—including the bore for the tensioner cylinder, seal running surfaces, and the track chain raceway—are finished on CNC equipment and subject to 100% inspection. Dimensional reports and material certifications are traceable for each production batch.

- Performance Testing: Assembled units undergo rotational torque analysis, seal leakage pressure tests, and radial load simulation to verify performance before release.

Value Proposition for Mining & Heavy Equipment Operations

For managers of EX1200-6 fleets in mining and heavy excavation, sourcing the idler assembly from expert manufacturer HELI CQCTRACK delivers measurable operational advantages:

- Guaranteed Mining-Duty Performance: Components are built to the original HITACHI 4696615 specification with enhancements focused on the most punishing applications, ensuring reliability where it matters most.

- Extended Wear Life & Predictability: The combination of superior materials, hardfacing, and sealing technology results in a more predictable and extended wear cycle, enabling better maintenance planning and reduced unscheduled downtime.

- Expert Technical Collaboration: As a manufacturer, HELI CQCTRACK provides direct engineering support for wear analysis and failure mode investigations, offering solutions rather than just parts.

- System-Wide Compatibility: Expertise extends to the full undercarriage system. Operators can source a perfectly matched set of idlers, rollers, sprockets, and track links, ensuring harmonic wear and optimal performance across all components.

Application, Maintenance & Procurement Notes

The HITACHI EX1200-6 Track Idler Wheel Assembly (4696615) is a critical consumable for:

- Scheduled undercarriage rebuilds in high-hour machines.

- Repair after impact damage or abnormal wear events.

- Proactive replacement to prevent costly secondary damage to track chains and frame components.

Procurement Specification: When sourcing, verify the manufacturer provides evidence of material grade, hardening depth reports, and seal brand/type. For mining applications, the provenance and technical validation of components are as important as price.

Conclusion

In the realm of ultra-class mining excavators, the idler wheel is a cornerstone of undercarriage integrity. The HITACHI EX1200-6 Track Idler Wheel Assembly manufactured by HELI CQCTRACK embodies a synthesis of precise OEM interchangeability and expert, application-driven enhancements. By leveraging specialized materials science, advanced manufacturing protocols, and a deep understanding of severe-duty operational challenges, HELI CQCTRACK delivers not just a component, but a engineered solution aimed at maximizing machine availability and minimizing the total cost of ownership for critical assets like the Hitachi EX1200-6.