Chinese Professional Bucket Tooth Excavator - DH360/370 2713-0032RC Bucket Teeth – Heli

Chinese Professional Bucket Tooth Excavator - DH360/370 2713-0032RC Bucket Teeth – Heli Detail:

Material: Special alloy steel

Length:314mm

Weight:11.1kg

Aperture:27mm

Impact energy:28J

Excavator bucket teeth is the important part of excavator for construction machinery,like human teeth.Bucket teeth is always fitted with the adapter using a pin. Common bucket teeth in the market are served for excavator like:Caterpillar,komatsu,Hitachi,Daewoo,ect.As bucket teeth is worked in a hard environment,so the wear-resistance is quite important,it will directly affect the working life and performance of products.Currently,main production processes of excavator bucket teeth can be:casting and forging.

FORGED BUCKET TEETH

Forged bucket teeth is the manufacturing process that putting pressure on the heated steel billet between the forging dies in high temperature,so that the material will full fill the forging dies,thus to achieve desired shape.In the forging process,the billet will be plastic deformed to obtain certain mechanical properties.Bucket teeth after forging processing can improve its organizational structure and guarantee a good mechanical performance,more wear-resisting, long service life.However,cast bucket teeth are made in the condition of high temperature molten metal and then injected in the casting molds,final cast bucket teeth are thus formed after cooling. By comparison,cast bucket teeth is more easy to products defects like air holes.And both the mechanical properties and wear resistant will be worse than that of forged bucket teeth,thus to affect the serving life of products.So we always suggest forging process for excavator bucket teeth.

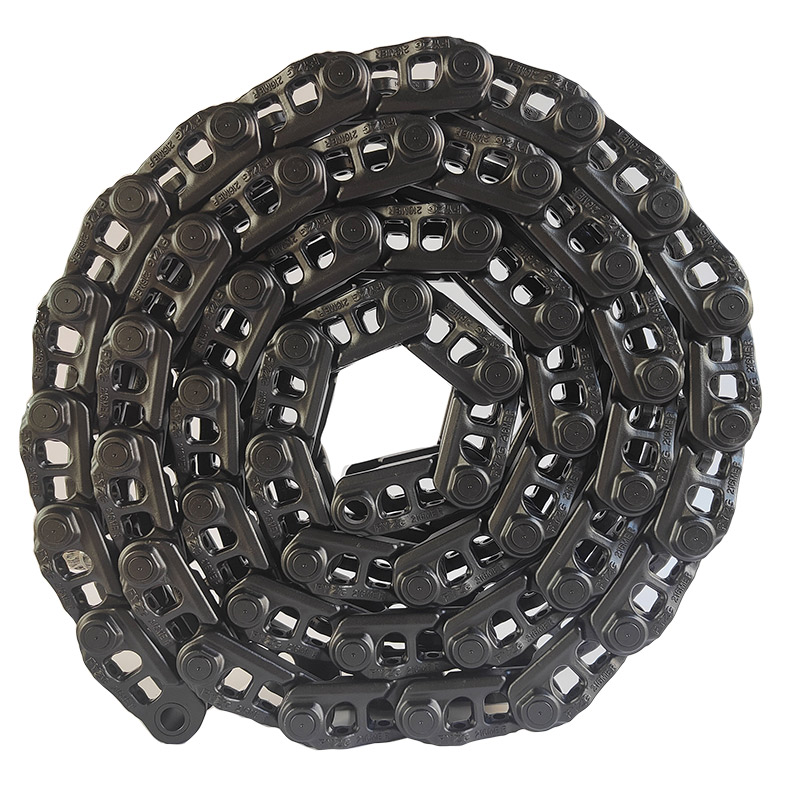

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for Chinese Professional Bucket Tooth Excavator - DH360/370 2713-0032RC Bucket Teeth – Heli , The product will supply to all over the world, such as: Pakistan, Provence, Iraq, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.