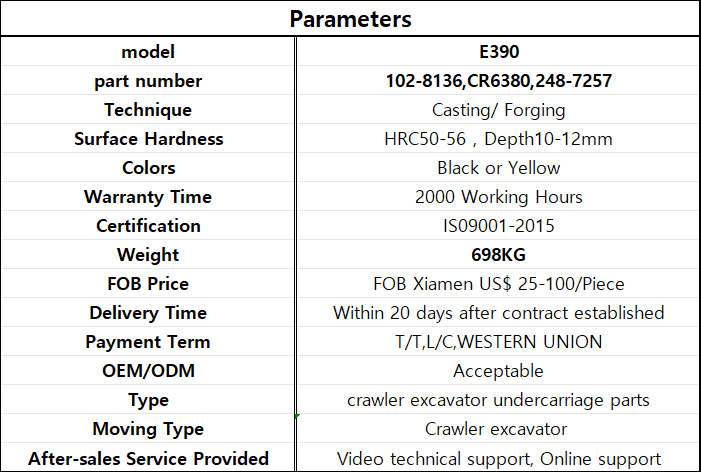

CATERPILLAR(102-8136,CR6380,248-7257)-E390 front idler Group-china idler factory-CQC-made all of the undercarriage parts

CATERPILLAR(102-8136,CR6380,248-7257)-E390 front idler Group-china idler factory-CQC-made all of the undercarriage parts

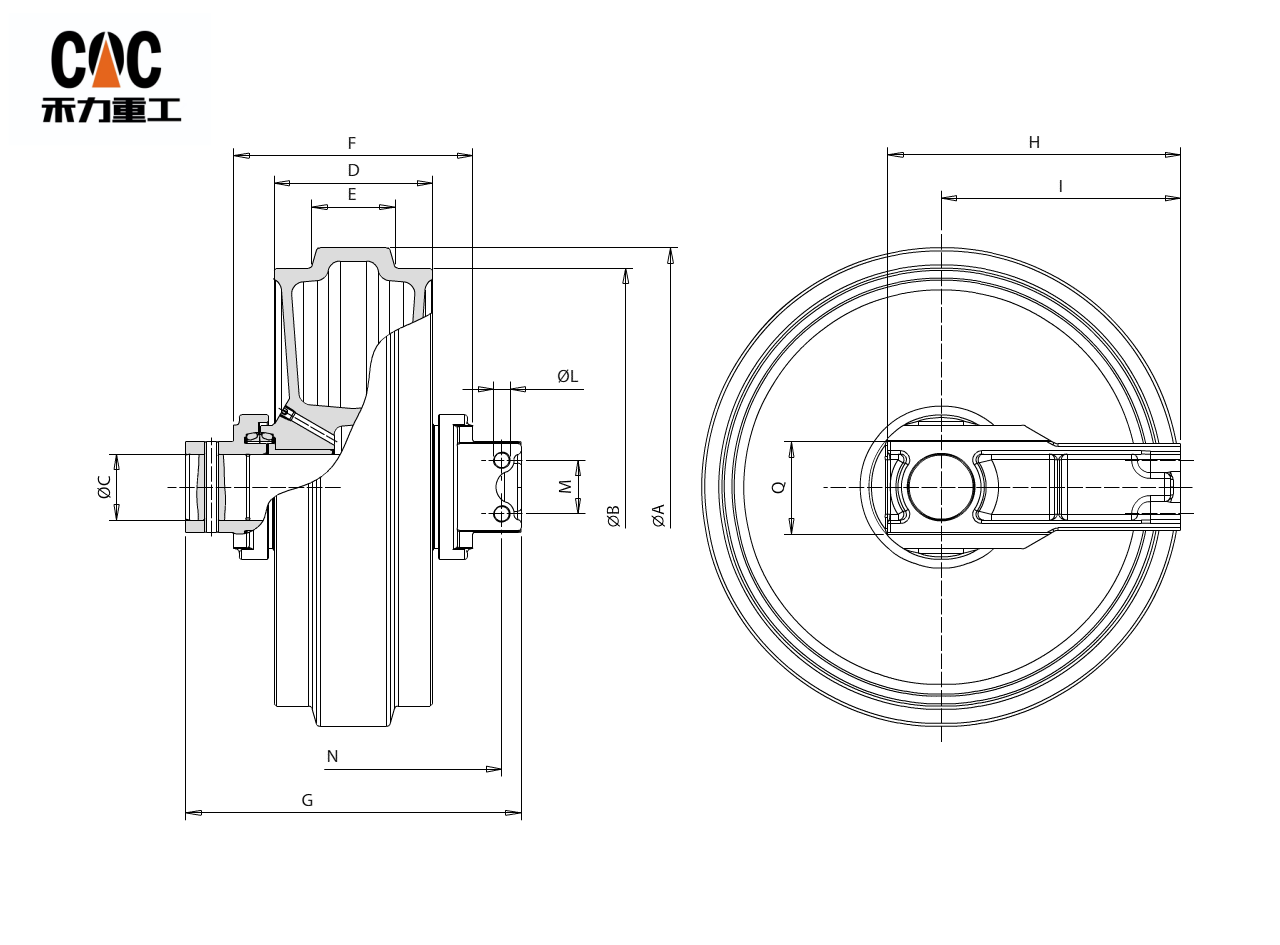

An excavator front idler (also called a track idler) is a key component of the undercarriage system, guiding and maintaining tension in the track chain. Here’s a detailed breakdown:

1. Function of the Front Idler

- Guides the Track Chain: Ensures smooth movement along the undercarriage.

- Maintains Track Tension: Works with the adjuster (grease or hydraulic) to keep proper tension.

- Supports Machine Weight: Helps distribute load across the track.

2. Types of Front Idlers

- Solid Idlers: One-piece design, common in standard-duty applications.

- Segmented Idlers: Made of multiple replaceable rings, reducing replacement costs.

- Flanged vs. Non-Flanged:

- Flanged Idlers prevent track derailment in rough terrain.

- Non-Flanged Idlers are used in specific machine designs.

3. Construction & Materials

- High-Carbon or Alloy Steel for durability.

- Hardened Surface to resist wear from track chain friction.

- Sealed & Lubricated Bearings to extend service life.

4. Signs of a Worn-Out Front Idler

- Excessive Track Slack (even after adjustment).

- Uneven Wear on the Idler Surface (grooves or flat spots).

- Track Misalignment or Derailment.

- Grinding or Squeaking Noises from the undercarriage.

- Visible Cracks or Damage on the idler wheel.

5. Maintenance & Replacement Tips

- Regular Inspection: Check for wear, cracks, and bearing play.

- Proper Track Tension: Adjust according to manufacturer specs.

- Replace in Pairs (both sides) for balanced performance.

- Use OEM or High-Quality Aftermarket Parts (CQC-TRACK).

- Clean Undercarriage frequently to prevent debris buildup.

6. Where to Buy

- OEM Dealers (Caterpillar, Komatsu, Hitachi, etc.).

- Undercarriage Specialists (cqctrack).

- www.cqctrack.com

7. Compatibility Considerations

- Excavator Model & Undercarriage Size (e.g., 300-class, 20-ton machines).

- Bolt Pattern & Mounting Style (must match the machine).

- Track Chain Pitch (must align with sprocket and rollers).

Write your message here and send it to us