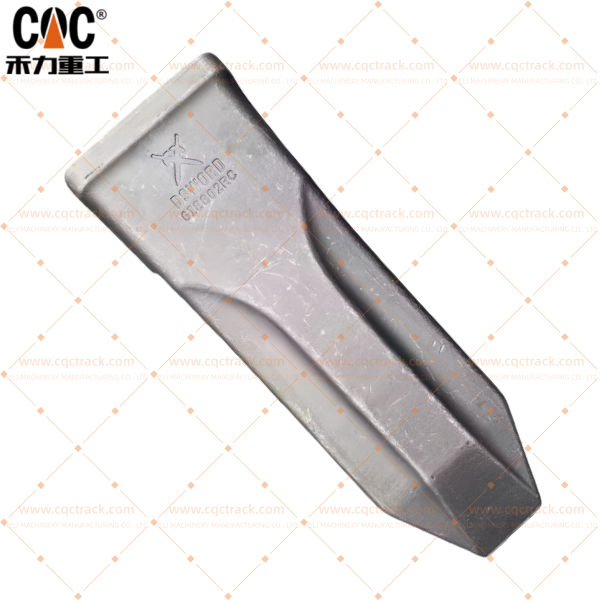

CATERPILLAR 6I8802RC J800 E390RC Forged Bucket Teeth | HELI Dsword | Bucket Teeth Manufacturing Specialist

High-performance CATERPILLAR 6I8802RC (J800/E390RC) forged bucket teeth by HELI Dsword. Expert engineering for superior penetration, wear life, and value in heavy excavation. Discover our focused manufacturing excellence.

Content:

Introduction: The Critical Role of Bucket Teeth in Earthmoving Efficiency

In the demanding cycle of excavation, loading, and material handling, bucket teeth are the primary point of contact and the most critical wear component. Their design, metallurgy, and manufacturing quality directly determine machine productivity, fuel efficiency, and operational cost. For Caterpillar® equipment utilizing the J800 (also known as E390RC) style adapters, the 6I8802RC tooth is a key wear part. HELI Dsword, as a specialist manufacturer focused solely on ground engagement tools (GET), engineers these teeth to deliver optimal performance and durability under extreme abrasion and impact.

Technical Specifications: CAT 6I8802RC / J800 / E390RC Forged Bucket Teeth

This tooth is designed for a balance of robust strength and efficient material penetration, commonly deployed on a range of Caterpillar excavators and loaders.

- OEM Part Number Reference: CATERPILLAR 6I8802RC

- Tooth System/Adapter: Compatible with the J800 adapter (also referenced under the E390RC system).

- Primary Applications: Ideal for general to heavy-duty excavation, trenching, and loading of mixed materials including soil, clay, gravel, and ripped rock.

- Key Design Features: The geometry is optimized to provide strong penetration with a streamlined profile that reduces drag resistance. The locking system interface is precision-machined to ensure a secure, rattle-free fit with the adapter, minimizing stress concentrations and loss.

HELI Dsword’s Engineering and Metallurgy Focus

As a dedicated bucket teeth manufacturer, HELI Dsword’s approach is rooted in material science and precise process control.

- Premium Forging Process: Unlike cast teeth, HELI Dsword’s 6I8802RC teeth are manufactured using closed-die forging. This process aligns the steel’s grain flow with the tooth’s contour, creating a continuous, unbroken grain structure that significantly enhances impact toughness and fatigue resistance. It eliminates internal voids and inclusions common in casting, providing more consistent and reliable mechanical properties.

- Advanced Alloy Steel Selection: We employ proprietary, developed Boron-based or low-alloy steels. These alloys are specifically formulated to respond exceptionally well to subsequent heat treatment, allowing for a deep, uniform hardness profile.

- Precision Heat Treatment: The core of our manufacturing focus is a controlled quenching and tempering (Q&T) process. This achieves an optimal balance between surface hardness and core toughness:Specialized Wear Enhancements: Select versions may feature Carbide-Enhanced Wear Zones. Strategically placed tungsten carbide inserts or a wear-resistant alloy overlay on critical wear surfaces (such as the top guard and front lip) dramatically extend service life in highly abrasive conditions.

- High Surface Hardness (HB 450-550): To resist abrasive wear from soil and rock.

- Tough, Ductile Core: To absorb high-impact shocks without brittle fracture or catastrophic failure.

Manufacturing Excellence: A Dedicated GET Facility

HELI Dsword’s focused manufacturing ecosystem ensures quality at every stage:

- Vertical Integration: From raw material analysis to forging, heat treatment, machining, and quality inspection, all processes are controlled in-house.

- Forging Precision: High-tonnage forging presses ensure dense, flaw-free metal formation.

- CNC Machining: The adapter pocket and locking pin bore are machined with high precision on CNC centers to guarantee perfect fit and easy installation/removal.

- Rigorous QC Protocol: Every production batch undergoes:

- Spectrochemical analysis to verify alloy composition.

- Hardness testing (Brinell/Rockwell) at multiple points.

- Dimensional checks using calibrated gauges and CMM for critical profiles.

- Charpy V-notch impact testing on sample lots to validate toughness.

Value Proposition and Operational Benefits

Choosing HELI Dsword’s forged CATERPILLAR 6I8802RC teeth provides tangible advantages:

- Extended Wear Life: Superior forging and heat treatment yield a more durable product, reducing change-out frequency and downtime.

- Improved Productivity: Optimized geometry maintains sharpness longer, ensuring faster bucket filling and lower machine strain.

- Cost Efficiency: Delivering OEM-comparable or superior performance at a competitive total cost per operating hour.

- Reliability: Forged construction and stringent QC minimize the risk of unexpected breakage, enhancing job site safety and predictability.

- Global Support: Available through a worldwide distribution network for timely supply.

Conclusion: A Focused Solution for Demanding Applications

The CATERPILLAR 6I8802RC J800/E390RC) Forged Bucket Tooth exemplifies HELI Dsword‘s dedicated philosophy as a bucket teeth manufacturer. By concentrating expertise on the metallurgy and precision manufacturing of Ground Engagement Tools, we deliver a component that is not just a replacement, but a performance upgrade. For fleet managers and equipment operators seeking reliable, high-value GET that maximizes the productivity of their Caterpillar machinery, HELI Dsword provides a robust, engineering-focused solution built to withstand the rigors of the modern worksite.

Disclaimer: CATERPILLAR, CAT, and related part numbers are trademarks of Caterpillar Inc. HELI Dsword is an independent manufacturer and supplier of aftermarket replacement parts and is not affiliated with Caterpillar Inc.