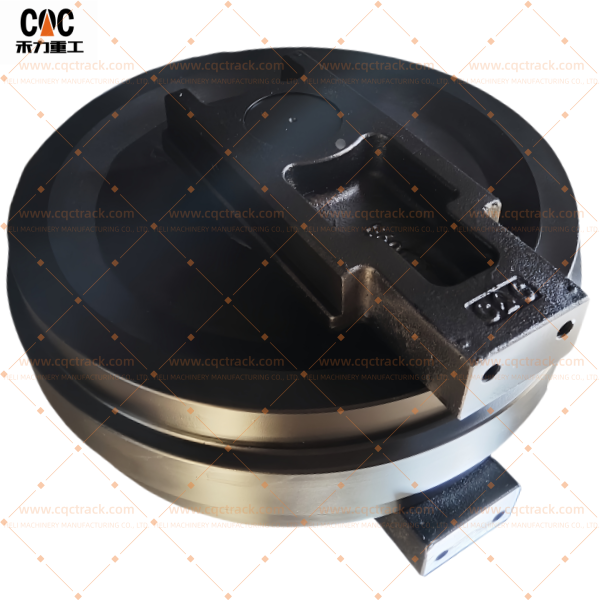

Caterpillar Track Idler Wheel Assembly (P/N: 430-4193, 650-5861, E6015/E6015B) | Mining-Grade Undercarriage Manufacturer | HELI (CQCTRACK)

Professional OEM manufacturer HELI (CQCTRACK) supplies heavy-duty track idler wheel assemblies for Caterpillar excavators (P/N: 430-4193, 650-5861, E6015/E6015B). Engineered for extreme mining environments with superior wear resistance, advanced sealing, and direct factory customization. Supports sample/ drawing-based ODM.

1. Product Overview: Critical Undercarriage Component for Cat® Excavators

The Track Idler Wheel Assembly is a foundational load-bearing component within the track-type undercarriage system of Caterpillar® heavy-duty crawler excavators. This assembly, identified by Caterpillar® part numbers 430-4193, 650-5861, and E6015/E6015B, is precisely engineered and manufactured by HELI (CQCTRACK), a global leader in undercarriage solutions. Functioning as the forwardmost point of the track frame, it serves to guide, tension, and support the endless track chain. Its performance is paramount for ensuring machine stability, efficient power transmission, and controlled track alignment under the most severe operating loads.

2. Engineered for Extreme Mining & Heavy-Duty Applications

Mining, quarry, and heavy construction environments subject undercarriage components to unparalleled stress from abrasive wear, high-impact shocks, and constant contamination. HELI’s Caterpillar-compatible idler assemblies are specifically fortified for these challenges:

- Ultra-Abrasion Resistant Running Surface: The idler wheel is crafted from premium forged and normalized alloy steel (e.g., 50Mn/60Si2Mn). The tread and flange profiles undergo computer-controlled induction hardening to achieve an optimal hardness depth profile. This results in a supremely hard surface (HRC 58-63) to resist grinding wear from track chain bushings, while maintaining a tough, ductile core (HRC 30-40) to absorb impact energy without cracking.

- Enhanced Structural Integrity for Shock Loading: The robust design, including a high-strength, heat-treated integral shaft and flange, is calculated to withstand the dynamic and shock loads encountered during travel over fragmented rock and uneven terrain, common in mining and major earthworks.

- Military-Grade Contaminant Exclusion: A proprietary multi-stage sealing system is employed. This typically combines a floating radial face seal, a heavy-duty labyrinth channel, and nitrile rubber dust lips. The cavity is pre-packed with high-viscosity, wide-temperature-range lithium-complex grease, creating a formidable barrier that excludes fine silica dust, slurry, and water even under high-pressure washdowns, drastically extending bearing life.

3. Technical Specifications & Performance Features

- Precision Manufacturing: Fabricated to exact original Caterpillar® dimensional specifications for outer diameter (OD), overall width, bore tolerance, flange geometry, and mounting bolt pattern. Guarantees perfect interchangeability and alignment.

- Core Construction & Materials:

- Wheel Rim: Forged alloy steel, deep case hardened.

- Shaft & Hub Assembly: High-tensile steel, precision machined, ground, and often surface-treated (e.g., chrome plating) for corrosion and wear resistance at critical interfaces.

- Bearing System: Utilizes large-bore, high-capacity tapered roller bearings for optimal management of both radial loads and thrust loads generated during machine turning.

- Sealing Assembly: Multi-component, labyrinth-design seals for maximum contaminant exclusion.

- Wear Components: Includes hardened, replaceable bushings or wear rings at the mounting interface to protect the idler housing and track frame structure.

- Performance Certification: Manufactured under a strict quality management system, with materials and processes designed to meet or exceed the performance benchmarks expected for Caterpillar® excavator undercarriage components.

4. Manufacturer’s Capability: HELI (CQCTRACK) Professional Profile

HELI (CQCTRACK) is a vertically integrated, specialist manufacturer with proven expertise in supplying to the global heavy machinery market.

- OEM/ODM Specialist: We operate as both a qualified OEM supplier and a full-service Original Design Manufacturer (ODM). We produce components to match original samples, precise engineering drawings (2D/3D CAD), or Caterpillar® part numbers with equal fidelity.

- Complete In-House Production Chain: Our integrated facility controls the entire process: material forging, CNC precision machining, automated heat treatment, robotic welding, assembly, and testing. This ensures quality control at every stage and competitive factory-direct pricing.

- Quality Assurance & Certifications: Our production is governed by an ISO 9001:2015 certified Quality Management System. Each batch undergoes rigorous checks including: material spectroscopic analysis, hardness and case depth verification, dimensional inspection via CMM, and rotational torque/leakage testing.

- R&D & Custom Engineering: Our technical team can provide value-engineered solutions and full customization, including material upgrades for specific abrasives, seal enhancements for wet conditions, or design adaptations for modified equipment.

5. Maintenance, Inspection & Optimal Service Life

- Preventive Maintenance: Adhere to regular lubrication schedules using the specified high-pressure, high-temperature grease. Inspect grease seals for damage during routine undercarriage cleaning.

- Wear Monitoring: Periodically measure the idler rim outer diameter and flange side thickness against allowable wear limits. Check for excessive axial and radial play, which indicates potential bearing or bushing wear.

- System-Wear Considerations: To achieve the best cost-per-hour and avoid premature wear, evaluate the idler’s condition in context with the track chain (especially pin and bushing wear), sprocket, and roller assemblies. Replacing severely worn components in a matched set is often the most economical long-term strategy.

- Correct Track Tension: Maintain track tension according to the manufacturer’s specifications. Improper tension is a leading cause of accelerated idler and track system wear.

6. Machine Compatibility & Application

- Primary Application: This assembly is designed as a direct replacement for Caterpillar® excavator models utilizing the specified part numbers. It is crucial to verify the exact machine model and serial number to ensure correct application.

- OEM Part Number Interchange: Direct replacement for Caterpillar® part numbers:

7. Factory Direct Sales & Customization Service

- Competitive Direct Pricing: By manufacturing and selling directly, HELI (CQCTRACK) offers significant value, providing OEM-comparable quality at highly competitive prices, especially for bulk and recurring orders.

- Sample & Drawing-Based Production: We actively encourage and support custom manufacturing based on provided samples or technical drawings. Our ODM service is ideal for customers with specific requirements or those seeking to develop their own branded undercarriage line.

- Global Logistics Support: We are experienced in international export, offering flexible trade terms (FOB, CIF, DAP, etc.) and providing professional export packaging and documentation for seamless delivery worldwide.

8. Comprehensive After-Sales Support & Warranty

- Technical Consultation: Our sales and engineering teams provide expert pre-sales and after-sales technical support for product selection, installation guidance, and troubleshooting.

- Product Warranty: All our track idler wheel assemblies are backed by a clear and standard warranty policy, covering defects in materials and workmanship.

- Reliable Supply & Parts Support: We maintain strategic inventory and production planning to ensure stable supply. We also offer related wear parts and components to support your maintenance ecosystem.

9. Conclusion

The Caterpillar 430-4193, 650-5861, E6015/E6015B Track Idler Wheel Assembly from HELI (CQCTRACK) embodies a commitment to durability, precision, and value. Engineered to survive in the world’s toughest mining and excavation environments, it delivers reliable performance that protects your equipment investment and maximizes operational uptime. As your trusted manufacturing partner, we combine advanced engineering, stringent quality control, and flexible customization to meet your exact undercarriage component needs.

Contact us today for a detailed quotation, technical specifications, or to discuss your custom ODM/OEM project requirements.