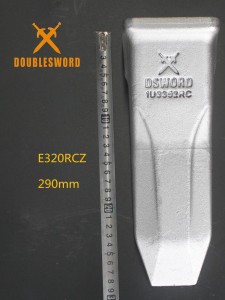

CATERPILLAR dozer 6Y3552TL D11 Forged Bucket tooth – Heavy duty excavator forged bucket tooth supplier and manufacturer-HELI (Dsword)

CATERPILLAR D11 Forged Bucket Tooth (6Y3552TL): Heavy-Duty Application Engineering by HELI (DSWORD)

Executive Technical Summary

HELI (DSWORD), a specialized supplier and manufacturer of heavy-duty forged excavator and dozer bucket teeth, presents its engineered forged bucket tooth for the CATERPILLAR D11 bulldozer, compatible with part number 6Y3552TL. This component is specifically designed for the extreme abrasion, high-impact loading, and continuous duty cycles characteristic of large-scale mining, quarrying, and major earthmoving projects. Utilizing proprietary forging metallurgy and precision manufacturing, this tooth delivers maximum penetration, wear life, and protection for the dozer blade corner.

1. Product Identification & Machine Application

1.1 Critical Function in Dozer Operation

The bucket (corner) tooth on a Caterpillar D11 is not merely a wear item but a fundamental productivity tool:

- Penetration & Cutting: The primary point for slicing into dense, compacted, or rocky materials.

- Blade Corner Protection: Shields the critical and expensive corner segment of the dozer blade from direct abrasive wear and impact damage.

- Load Initiation: Begins the material rolling action essential for efficient dozing.

1.2 Target Machine & System Compatibility

- Primary Application: CATERPILLAR D11 Track-Type Tractor (D11T, D11T CD, and applicable older variants).

- Compatible Adapter System: Designed to interface precisely with the CAT 6Y series adapter/lock system (e.g., 6Y3551 Adapter). Ensures secure mechanical lock-up without modification.

- OEM Reference: Direct replacement for CATERPILLAR part number 6Y3552TL.

2. Manufacturing Excellence: The HELI Forging Advantage for Ultra-Class Equipment

Forging is the only viable manufacturing process for components subjected to the stresses encountered by a D11 tooth. HELI (DSWORD) employs a precision hot-forging and controlled heat-treatment regimen.

2.1 The Integrated Forging Process

- Alloy Steel Formulation: Selection of a premium, air-melted alloy steel with specific levels of carbon, chromium, boron, and other micro-alloys to achieve an optimal balance of surface hardness and core toughness.

- Hot Die Forging: The steel billet is heated and formed under extreme pressure (thousands of tons) within precision-machined forging dies. This aligns the metallic grain structure along the tooth’s shape, creating inherent strength far superior to castings.

- Normalization & Heat Treatment: A meticulously controlled sequence involving austenitizing, quenching, and tempering. This develops a graded hardness profile: a supremely hard, wear-resistant working surface (approximately 470-530 HB) supported by a tough, ductile core to resist bending and shock fracture.

- CNC Finish Machining: Critical areas, especially the lock pocket and bore, are machined to exacting tolerances. This guarantees a perfect, secure fit with the adapter, eliminating harmful movement that accelerates wear on both the tooth and adapter.

- Non-Destructive Testing (NDT): Select samples undergo testing to verify internal integrity and absence of forging defects.

2.2 Why Forged Teeth are Essential for the D11

- Superior Fatigue Life: The forged fibrous grain structure withstands the repeated high-cycle loading of dozing without developing subsurface cracks—a common failure point in cast teeth.

- Exceptional Impact Resistance: The tough core prevents catastrophic breakage when impacting large, unyielding rock formations.

- Optimal Abrasion Resistance: The dense, non-porous forged material provides uniform wear, maintaining a sharp(er) cutting edge longer than cast alternatives.

- Reliability: Predictable wear patterns and reduced risk of sudden failure protect against costly unscheduled downtime and potential damage to the blade assembly.

3. Technical Specifications & Design Features

3.1 Material & Metallurgical Properties

- Material: HELI-proprietary alloy forging steel.

- Hardness Profile: Working surfaces hardened to 470-530 Brinell (HB); core toughness maintained for impact absorption.

- Microstructure: Fine, tempered martensitic/bainitic structure achieved through controlled quenching.

3.2 Engineered Design

- Penetration-Optimized Geometry: Profile designed to reduce cutting resistance and promote efficient material flow over the blade.

- Reinforced Nose & Lock Area: Extra material volume in high-stress zones to combat deformation and ensure the locking mechanism remains fully engaged.

- Precision-Machined Interfaces: Locking grooves and bore are machined to guarantee a flush, tight fit, maximizing force transfer and stability.

4. HELI (DSWORD) Capabilities: A Heavy-Duty Forging Specialist

Our identity as a dedicated heavy-duty forged bucket tooth manufacturer is built on integrated, controlled production:

- Full Process Control: In-house management from alloy specification and die design to final machining and packaging.

- Modern Forging Infrastructure: High-capacity, computer-monitored forging presses and automated heat treatment lines ensure batch-to-batch consistency.

- Rigorous Quality Assurance: Full compliance with ISO 9001 standards. Quality checks include spectral chemical analysis, hardness mapping, dimensional verification via CMM, and load testing.

- Application Engineering Support: Technical expertise to support customers in selecting the optimal wear solution for their specific material conditions (e.g., highly abrasive vs. high-impact).

5. Economic & Operational Value Proposition

For D11 operators, the choice of teeth directly impacts profitability:

- Maximized Production Uptime: Extended wear life reduces change-out frequency, increasing machine availability for production.

- Lower Cost-Per-Hour (CPH): The combination of superior wear life and protection of the base machine (adapter and blade) results in the lowest total operating cost.

- Consistent Performance: Maintains efficient dozing performance throughout its service life, avoiding the productivity drop associated with badly worn teeth.

- Reduced Inventory & Logistics: Longer life means fewer teeth are consumed per operating period, simplifying supply chain management for large-scale operations.

Conclusion

The CATERPILLAR D11 Forged Bucket Tooth (6Y3552TL) from HELI (DSWORD) is engineered to meet the extraordinary demands of the world’s largest dozing applications. By leveraging advanced forging technology, metallurgical science, and precision manufacturing, we deliver a component that provides unmatched durability, reliability, and value. For mine and quarry managers seeking to optimize the performance and cost-effectiveness of their ultra-class equipment, HELI (DSWORD) stands as a trusted partner in heavy-duty wear part solutions.