CAT 1787293,1524182,1231379 E345 Track Roller Assembly | Heavy-Duty Excavator Undercarriage Components Manufacturer & Supplier | HELI (CQCTRACK)

As a leading manufacturer, HELI (CQCTRACK) supplies premium CAT-tracked excavator undercarriage parts. Discover our precision-engineered, durable CAT 1787293,1524182,1231379, and E345 track roller assemblies, built to exceed OEM specifications for extreme-duty applications.

The Critical Role of Track Roller Assemblies in Excavator Performance

The undercarriage is the foundational chassis system of any tracked excavator, bearing immense static and dynamic loads while ensuring mobility across challenging terrains. At the heart of this system are the track roller assemblies, components paramount for supporting the machine’s weight, guiding the track chain, and absorbing severe impact shocks. Failure in these components leads to accelerated wear on adjacent parts, increased fuel consumption, and costly unplanned downtime. HELI (CQCTRACK), as a specialized manufacturer and supplier, engineers and produces track roller assemblies that are direct replacements for Caterpillar® components, including part numbers 1787293, 1524182, 1231379, and for models like the E345. Our commitment is to deliver not just equivalence but superior durability and performance in heavy-duty and extreme working conditions.

Technical Specifications & Engineering Design Philosophy

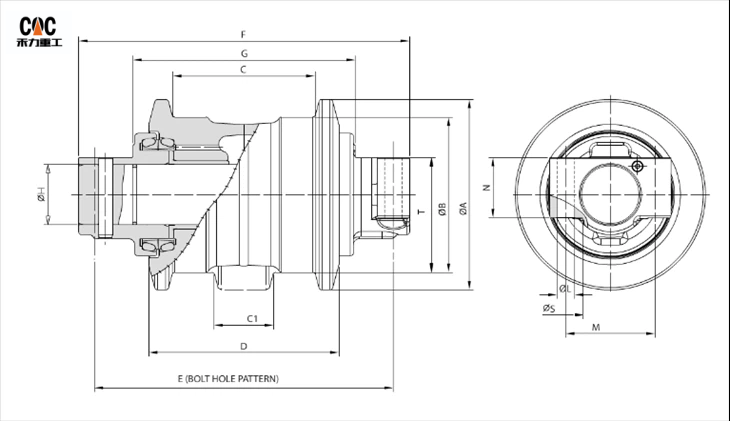

Our track roller assemblies are reverse-engineered and precision-manufactured to match or exceed the original dimensional, mechanical, and performance specifications. The design incorporates a holistic understanding of load distribution, material science, and sealing technology.

- Material Science: We utilize high-grade, forged alloy steel (e.g., SCr440, SAE 8620) for rollers and shafts, subjected to rigorous spectrometric analysis. This ensures optimal tensile strength, yield strength, and hardness profiles to resist deformation, abrasion, and rolling-contact fatigue.

- Heat Treatment Process: Components undergo controlled carburizing or induction hardening processes. This creates a deeply hardened exterior surface (typically 58-62 HRC) for exceptional wear resistance, while maintaining a tough, ductile core to withstand high-impact loads without catastrophic failure.

- Precision Machining & Tolerance: Advanced CNC grinding and machining centers guarantee micron-level tolerances on bore diameters, journal surfaces, and flange dimensions. This precision ensures perfect concentricity, minimizes vibration, and promotes seamless integration with the track link and bushing, extending overall undercarriage life.

- Sealing System Integrity: The most critical advancement lies in our multi-barrier sealing system. We employ a combination of:

- Nitrogenated Rubber (NBR) or Hydrogenated Nitrile (HNBR) Main Seals: For superior resistance to abrasion, ozone, and temperature extremes.

- Anti-Friction Floating Seals (Duo-Cone or Multi-Lip Design): These precision-ground metal face seals maintain a consistent lubricant film, effectively excluding contaminants like mud, sand, and slurry.

- Optimized Grease Cavity: Designed to maintain adequate lubricant volume and pressure, reducing internal friction and heat generation.

Manufacturing Process & Quality Assurance Protocol

HELI’s manufacturing is vertically integrated, allowing strict control over every production phase, from raw material procurement to final assembly.

- Forging & Initial Forming: High-precision die forging enhances grain flow and eliminates internal defects, providing a stronger metallurgical structure than cast alternatives.

- Machining: Multi-stage CNC turning, milling, and drilling create the precise geometry. Critical sealing surfaces are finish-ground to a mirror-like Ra ≤ 0.8 µm.

- Heat Treatment: Computer-controlled atmosphere furnaces ensure uniform case depth and hardness. Tempering follows to relieve stresses and achieve the desired core toughness.

- Seal Assembly & Lubrication: Seals are assembled in a clean-room environment. Rollers are filled with a high-performance, lithium-complex extreme-pressure (EP) grease via automated purging systems to eliminate air pockets.

- Comprehensive Testing: Each batch undergoes:

- Dimensional Metrology: CMM (Coordinate Measuring Machine) verification.

- Hardness Testing: Rockwell and Brinell tests at multiple points.

- Rotational Torque Test: Ensures smooth rotation without excessive drag or free play.

- Seal Leakage Test: Submersion and pressure differential tests to confirm sealing integrity.

- Dynamic Load Simulation (Sampling): Simulated field conditions to validate lifespan under load.

Application-Specific Durability & Compatibility

Our track roller assemblies are engineered for a wide range of severe applications:

- Mining & Quarrying: Withstanding constant impact from large rocks and abrasive dust.

- Heavy Construction: Resilient in muddy, wet, and uneven terrain conditions.

- Demolition: Capable of handling shock loads from debris and unstable ground.

- Forestry: Protected against penetration from woody material and high-moisture environments.

Compatibility: Our parts are designed as direct, bolt-on replacements for corresponding Caterpillar® excavator models. For example, the E345-specific roller assembly is engineered to match the exact load ratings and mounting specifications of that machine.

Why HELI (CQCTRACK) is Your Strategic Supply Partner

- OEM-Level Engineering: Dedicated R&D team focused on undercarriage components, utilizing FEA (Finite Element Analysis) for design optimization.

- Full Process Control: From steel mill to finished product, ensuring traceability and consistent quality.

- Agile Supply Chain: Ability to produce large volumes with flexible MOQs, supported by robust logistics for global delivery.

- Technical Support: Provides detailed cross-reference guides, installation manuals, and wear-part analysis to support maintenance planning.

- Cost-Effectiveness: Delivering a superior total cost of ownership (TCO) through longer service intervals and reduced secondary damage, compared to generic aftermarket parts.

Conclusion: Invest in Undercarriage Longevity with HELI Precision

Choosing the correct track roller assembly is a decisive factor in maximizing excavator uptime and profitability. HELI (CQCTRACK) provides a technologically advanced, reliable, and cost-efficient solution for CAT 1787293, 1524182, 1231379, E345, and other critical undercarriage components. We invite distributors, rental companies, and mine operators to partner with us for a supply chain solution built on engineering excellence and proven performance.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||